If you’re a new miner, a mining contractor about to start work at a mine, or just someone interested in the mining industry, you’ve probably come across the acronym, MSHA (pronounced “EM-sha”), quite a bit. What is MSHA? What do they do? What type of training does MSHA require for miners and mining contractors? Don’t worry. You’re not the only person with loads of questions, but we’ve got the answers. In this article, we’ll review some of the most common questions about MSHA and offer some detailed answers to help keep you informed and compliant throughout your introduction to MSHA, the Mine Safety and Health Administration.

So, what are the 27 most commonly searched questions about MSHA? The 27 most commonly searched questions about MSHA are:

- What is MSHA?

- What does MSHA do?

- What is MSHA’s jurisdiction?

- Why was MSHA created?

- How is MSHA funded?

- What is MSHA Part 46 and Part 48?

- What does MSHA training consist of?

- Does MSHA accept online training?

- Is MSHA part of OSHA?

- How is MSHA different from OSHA?

- Are miners covered by OSHA?

- What is MSHA’s State Grants Program?

- What is the MSHA TRAM conference?

- What are MSHA-approved products?

- What is an MSHA mine ID?

- What is an MSHA blue card?

- How long does MSHA certification last?

- Does MSHA require drug testing?

- What are MSHA Rules To Live By?

- What are MSHA Fatalgrams?

- How much do MSHA inspectors make?

- What is an MSHA reportable injury?

- What is an MSHA Order?

- Can MSHA fine an individual / employee?

- What is MSHA EPD?

- What is MSHA Hazcom?

- What is the MSHA silica standard?

MSHA is simply a U.S. federal organization that oversees surface and underground mines. While that sounds pretty straightforward, most people are left with loads of questions about who MSHA is and what MSHA actually does. And many people aren’t quite sure how MSHA is different from OSHA (the Occupational Safety and Health Administration). Well, we’ll cover that and many more questions that just about everyone seems to have about this unique organization.

1. What is MSHA?

The acronym, MSHA, stands for the Mine Safety and Health Administration, a division of the US Department of Labor that oversees and enforces the federal safety and training regulations related to American surface and underground mines.

MSHA’s mission is to “prevent death, illness, and injury from mining and promote safe and healthful workplaces for U.S. miners.”

With that mission in mind, MSHA is granted the authority to uphold the provisions of the Federal Mine Safety and Health Act of 1977, typically referred to as the Mine Act. The Mine Act was amended by the Mine Improvement and New Emergency Response (MINER) Act of 2006.

2. What does MSHA do?

With its primary goal of protecting miners, MSHA carries out numerous activities within its authority, including:

- Advocating for miners’ rights and safety

- Developing and enforcing safety and health policies and regulations

- Providing industry education and training

- Conducting annual mine inspections (4 at all underground mines / 2 at all surface mines)

- Assisting with mine emergencies

- Performing accident investigations

- Enforcing safety violations by issuing citations and corrective orders

- Assessing and collecting civil penalties for mining violations

- Approving mining products

- Cooperating with other governmental agencies and sharing data and information

- Providing public access to safety statistics and fatality reports

Ultimately, while MSHA carries out many important administrative functions, its core activities involve providing:

- Safety oversight and enforcement,

- Miner advocacy, education and training, and

- Regulatory development as needed to improve safety for American miners.

3. What is MSHA’s jurisdiction?

This can be a tricky question to answer, because there are times when MSHA’s jurisdiction may be contested. But let’s start with the basics.

The Mine Act states that Mines Subject To [the] Act are “each coal or other mine, the products of which enter commerce, or the operations or products of which affect commerce, and each operator of such mine, and every miner in such mine shall be subject to the provisions of this Act.”

When there is a dispute about whether MSHA or OSHA has jurisdiction over worker safety in a specific situation at a mine, mill, or processing plant, the decision must be presented first to a field office, then to district manager, and ultimately to the Department of Labor in cases where local entities are unable to decide.

Jurisdictional lines and communication protocols are outlined in the 1979 Interagency Agreement Between MSHA and OSHA. More on that in a later question.

4. Why was MSHA created?

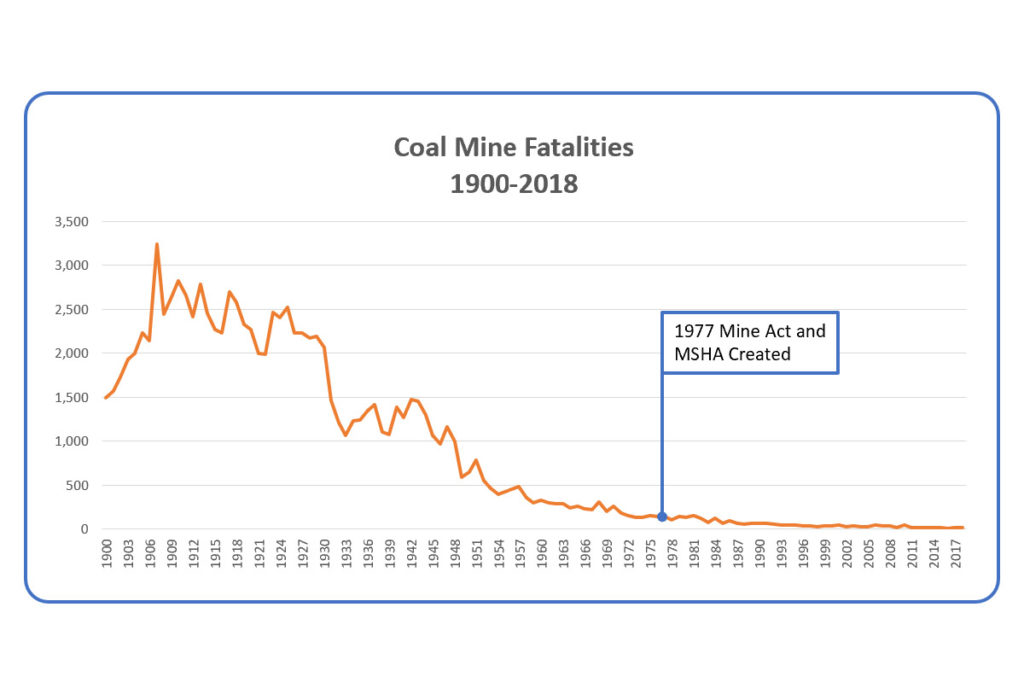

MSHA was created to improve safety and reduce injuries and fatalities in the U.S. mining industry.

With the passage of the 1977 Mine Act, the Department of Labor created MSHA to carry out the provisions of the new safety and health regulations.

Beginning in 1941 with the first law granting federal inspectors the right to enter and inspect coal mines, a series of impactful standards and acts followed in successive decades providing increased governmental oversight and influence on miner safety. The continued focus on mine safety significantly and consistently reduced overall fatalities. And since the 1977 Mine Act, fatalities have remained relatively low, though mining industry has yet to achieve zero fatalities in a given year.

5. How is MSHA funded?

Like other federal agencies, MSHA receives an annual budget through the federal government via an appropriations bill ultimately signed into law by the president.

For fiscal year 2019, MSHA’s budget remained unchanged from the prior year at $373.5 million. Comparatively, OSHA’s 2019 budget increased by $5 million from 2018 to $557.8 million.

While MSHA receives payments for several services and functions, those funds are sent to the Department of the Treasury and not considered revenue for directly funding MSHA operations. Examples include:

- Mine operator permits and reclamation bonds

- Tuition, training materials and publications, and certifications

- Civil penalties for health and safety violations

6. What is MSHA Part 46 and Part 48?

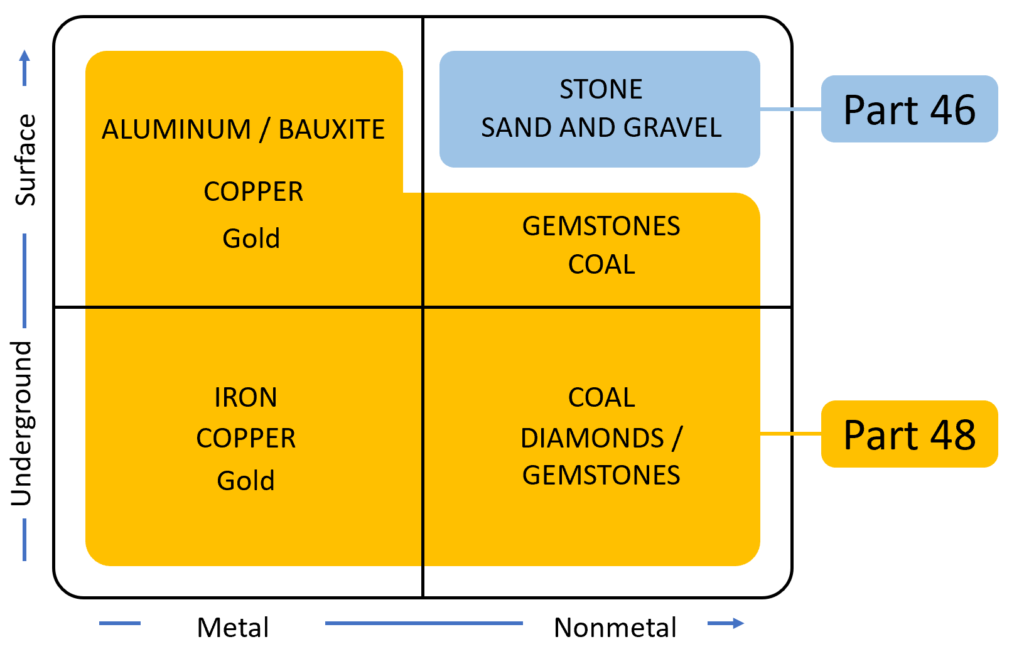

MSHA Part 46 and Part 48 are separate parts of Title 30 Code of Federal Regulations (CFR) which establish standards for mine safety and training.

Part 46 is for the “training and retraining of miners and other persons at shell dredging, sand, gravel, surface stone, surface clay, colloidal phosphate, and surface limestone mines.” This part is essentially for surface, non-coal, non-metal mines.

Part 48 is comprised of subparts A and B.

Part 48 A is for the “for training and retraining miners working in underground mines.”

Part 48 B is for the “training and retraining miners working at surface mines and surface areas of underground mines.” In this description, “surface mines” is referring to coal, metal, or gemstone surface mines not covered by Part 46.

TIP! – Check out our article “MSHA Part 46 vs Part 48 – The 3 Major Differences” for more detailed information on these regulations.

7. What does MSHA training consist of?

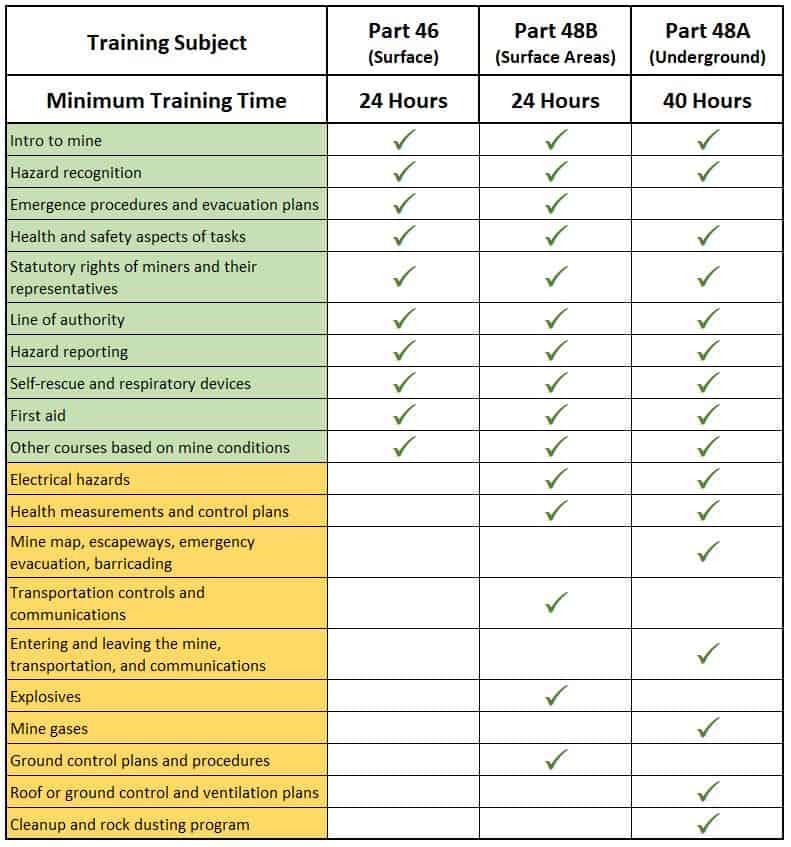

MSHA training for miners and mining contractors is very generally split into either Part 46 for surface miners, or Part 48 for underground miners. But as you might expect, it gets a bit more complicated than that.

The type of training required by MSHA depends entirely on what type of mine where you’ll perform work. In the prior answer above, we cover what types of mines MSHA Part 46 and Part 48 cover. And there are several very important differences in the time, subjects, and methods required for surface and underground mines.

This chart outlines and compares the required subjects for both Part 46 and Part 48 training.

TIP! – Check out our article “MSHA Part 46 vs Part 48 – The 3 Major Differences” for more details on training requirements for both surface and underground miners.

8. Does MSHA accept online training?

Yes, MSHA accepts online training for both Part 46 and Part 48. However, there are some important differences between the two. First, let’s clarify how MSHA views online training.

MSHA considers online or computer-based training a “training method” to be used by a competent person or approved instructor. As a training method, online training does not take the place of an instructor and the online training provider is not considered the competent person.

MSHA accepts online training as a training method for Part 46 surface miner training. However, the competent person must remain available during online training to answer questions that the miner may have.

MSHA also accepts certain online courses for Part 48 underground training from approved providers as long as the training is delivered or moderated by an MSHA-approved Part 48 trainer.

TIP! – Check out our article “Yes, MSHA Accepts Online Training – 5 Key Tips For Compliance” for more on MSHA and online training.

9. Is MSHA part of OSHA?

No, MSHA is not part of OSHA. The Mine Safety and Health Administration and the Occupational Safety and Health Administration are two separate agencies within the U.S. Department of Labor.

OSHA has authority over private sector employees and their workers except when another federal agencies or approved state programs have jurisdiction.

MSHA has authority over all U.S. mines, mine employees, and mining contractors when performing work at mining operations.

10. How is MSHA different from OSHA?

While the Occupational Safety and Health Act of 1970 grants OSHA the authority over all working conditions of employees, there are exceptions for conditions which other federal agencies have statutory authority and jurisdiction. So, in the case of mine employees and mining contractors, OSHA steps aside with respect to MSHA’s authority and jurisdiction over U.S. mines.

However, the lines can get a little blurry when their authorities may either overlap or be unclear. That’s why MSHA and OSHA entered into a 1979 Interagency Agreement to clarify and coordinate the jurisdictional authority, enforcement procedures, and communication protocols between their organizations.

One important difference is the way that the two agencies oversee safety training.

- OSHA provides and certifies outreach safety training directly to individuals in the form of OSHA 10 and 30-hour programs. The individual carries a certification card with them. However, it is state governments and employers, not OSHA, who require that individuals acquire this certification.

- MSHA enforces training regulations but requires that training be managed by the mine operator, not the individual miner. While MSHA provides instructor training and approval, the individual miners and mining contractors who receive the training don’t retain their “certifications” personally. They can retain copies of their training certificates, but it’s the mine operator or mining contractor who must maintain compliant training records.

11. Are miners covered by OSHA?

In certain cases, yes. The 1979 Interagency Agreement between MSHA and OSHA outlines in more detail where the lines between the two organizations are drawn.

This agreement states that “where the provisions of the Mine Act either do not cover or do not otherwise apply to occupational safety and health hazards on mine or mill sites (e.g., hospitals on mine sites) or where there is statutory coverage under the Mine Act but there exist no MSHA standards applicable to particular working conditions on such sites, then the OSHAct will be applied to those working conditions. Also, if an employer has control of the working conditions on the mine site or milling operation and such employer is neither a mine operator nor an independent contractor subject to the Mine Act, the OSHAct may be applied to such an employer where the application of the OSHAct would, in such a case, provide a more effective remedy than citing a mine operator or an independent contractor subject to the Mine Act who does not, in such circumstances, have direct control over the working conditions.”

Essentially, this means that OSHA may take precedent at a mine in situations where:

- No MSHA standards exist that apply to a certain working condition, and

- OSHA regulations may be more effective

12. What is MSHA’s State Grants Program?

MSHA’s State Grants Program provides financial support to mandated training for miners through U.S. states, territories, and the Navajo Nation.

Grants are made primarily to state agencies and educational institutions for health and safety training programs and efforts that support MSHA’s mission “to prevent death, illness, and injury from mining and promote safe and healthful workplaces for U.S. miners.”

The Mine Act gives the right to any state in which mining takes place to apply for a grant from MSHA. If a grant is awarded, funds from MSHA may account for 80% of the recipient’s education and training activities. The recipient must fund the remaining 20% of the training program cost.

In 2018, MSHA awarded over $10.5 million to recipients of its State Grants Program.

13. What is the MSHA TRAM conference?

MSHA’s TRAM (Training Resources Applied to Mining) conference is an annual meeting at the National Mine Health and Safety Academy in Beaver, WV. The conference is intended to be a venue for thought leadership and bring new ideas and innovations to the mine training community.

The conference includes presentations, workshops, an exhibit hall, and a mine-related training material competition.

14. What are MSHA-approved products?

MSHA approved products are products that have been evaluated and tested by MSHA’s Approval and Certification Center (A&CC) to meet strict safety and operational standards for use in “underground coal and gassy underground metal mines.”

Product manufactures must apply for approval based on MSHA’s compliance guides that outline regulations for products in areas of:

- Electrical Safety – related to electrical products

- Mechanical and Engineering Safety – related to diesel equipment

- Applied Engineering – related to refuge alternative products including proximity detection and emergency communication

MSHA publishes a monthly list of approved products.

15. What is an MSHA mine ID?

An MSHA Mine ID is a 7-digit unique identifying number required for each U.S. underground and surface mine site before any operations may begin.

Independent contractors performing services or engaged in construction work at a mine may also apply for an MSHA Contractor ID. And certain personnel applying for specific certifications, qualifications, or approvals are required to file for an MSHA Individual Identification Number (MIIN).

Filing for an MSHA Mine ID online is free.

16. What is an MSHA blue card?

An MSHA blue card refers to the certification card issued to an MSHA approved instructor for Part 48 underground miner training. A “blue card” is issued to an individual who has successfully completed an MSHA course for Part 48 instructors and has become approved to train miners at underground and surface areas of underground miners.

The blue card displays the (MIIN) Instructor Surface (IS) or Instructor Underground (IU).

It’s important to understand what an MSHA approved instructor is because Part 48 regulations require that all training be conducted by approved instructors. For Part 46 surface miner training, MSHA allow training to be conducted by a “competent person” deemed competent in training subjects by the mine operator. Part 46 training does not require an MSHA approved instructor.

It’s also important to understand that a Part 48 MSHA approved instructor is automatically authorized to train for Part 46. But that’s not the case for a Part 46 competent person. The competent person may only train Part 46 subjects.

And if you’ve completed training as a Part 48 underground miner or mining contractor, you are considered to have met the training requirements for Part 46 surface mines.

17. How long does MSHA certification last?

We’ll have to clarify exactly what’s meant by MSHA “certification,” because there can be some confusion between the idea of a personal certification, like an OSHA 10-Hour course or forklift operation certification, compared to MSHA’s use of the words “compliance” and “approval.”

Let’s use the examples of a miner who completes required training as “compliant” and an instructor who completes a Part 48 instructor training program as “approved.”

As a miner who successfully completes training, you’ve met MSHA’s training requirements, but that’s not technically a certification in the same way that you may receive a certification for operating a certain type of equipment. For example, when you’ve completed a New Miner training, you’ll be required to complete Annual Refresher training within 12 months of beginning work at a mine. And you’ll need to repeat that Annual Refresher training within every following 12 months to maintain compliance.

So, the “certification” of your training as a miner or mining contractor effectively lasts no longer than 12 months before requiring refresher training.

As a Part 48 approved instructor, you can be approved by MSHA to provide instruction for Part 48 training after successfully completing an MSA

HA Part 48 instructor program. Once approved, you may remain approved indefinitely. There is no specified renewal or refresher period for an approved instructor. However, your approval can be revoked for due cause or if you fail to provide miner training at least once every 24 months.

18. Does MSHA require drug testing?

No, MSHA doesn’t have regulatory or policy requirements specific to annual, random, incident, cause, or pre-employment drug testing.

CFR 30 – Part 56.20001 – Intoxicating Beverages and Narcotics states that “Intoxicating beverages and narcotics shall not be permitted or used in or around mines. Persons under the influence of alcohol or narcotics shall not be permitted on the job.”

Beyond that, MSHA leaves management of controlled substances, drug testing, and determinations of impairment up to the mine operator and mining contractor.

So, while MSHA doesn’t currently impose a regulatory standard for drug testing, that doesn’t mean that the mining industry doesn’t conduct employee drug tests. Many mines do have testing programs.

19. What are MSHA Rules To Live By?

MSHA’s “Rules to Live By” (RLB) is a series of initiatives that began in 2010 with the goal of preventing mining fatalities. The main idea is to focus on the most cited accidents and causes of mine fatalities to inform and prevent injury and death.

Rules to Live By I – Fatality Prevention – focused on 24 frequently cited standards in 9 accident categories:

- Falls from Elevation

- Falls of Roof and Rib

- Operating Mobile Equipment (Surface)

- Operating Mobile Equipment (Underground)

- Maintenance

- Lock and Tag Out

- Struck by Mobile Equipment (Surface)

- Struck by Mobile Equipment (Underground)

- Blocking Against Motion

Rules to Live By II – Preventing Catastrophic Accidents – focused on 9 standards cited due to mine disasters in 4 accident categories:

- Mining Methods

- Explosions

- Aftermath of a Fire

- Exams

Rules to Live By III – Preventing Common Mining Deaths – focuses on 14 standards due to recent mining fatalities.

Through the RLB outreach program, MSHA provides mine operators and miners’ representatives a range of information, reports, posters, training materials, and other resources to support efforts to improve workplace safety.

20. What are MSHA Fatalgrams?

MSHA Fatalgrams are one of two main types of documents that MSHA provides related to each fatal accident at a mine. The two documents are:

Fatality Alert (Fatalgram) – These notices provide basic information about the fatal incident and proposed best practices for avoiding future accidents.

Fatal Investigation Report – This document is released after an investigation has taken place and provides significantly greater detail about the accident and the physical factors involved along with accident conclusions and enforcement actions.

The purpose of this information is to educate and inform everyone in the industry of the real dangers that exist and urge miners and mine operators to take actions to avoid future accidents.

TIP! – Check out our article, “5 Most Common Mine Fatalities – Probably Not What You’d Think” for details on MSHA fatalities.

21. How much do MSHA inspectors make?

Based on 2019 MSHA job postings, here are the starting annual salaries for a selection of available positions:

- Supervisory Mine Safety and Health Specialist – $124,475

- Mine Safety and Health Specialist – $74,596

- Civil Penalty Compliance Technician – $42,308

- MSHA Safety and Health Inspector – $42,089

22. What is an MSHA reportable injury?

In Title 30 CFR Part 50 Subpart B – Notification, Investigation, Preservation of Evidence, MSHA outlines requirements for notification during specific types of events at a mine.

However, always call 9-1-1 FIRST in the event of a life-threatening emergency.

The types of emergencies that require immediate reporting within 15 minutes of the time a mine operator knows or should have known about the emergency include any of these incidents:

Death or Injury

- Death at a mine

- Event at a mine which causes death or bodily injury to an individual not at the mine at the time the event occurs

- Injury at a mine with potential to cause death

Fire or Explosion

- Unplanned ignition or explosion of gas, dust, blasting agent, or explosive

- Underground mines – Unplanned fire not extinguished within 10 minutes of discovery

- Surface mines and surface areas of underground mines – Unplanned fire not extinguished within 30 minutes of discovery

Inundation, Entrapment, Collapse, or Equipment Failure

- Unplanned inundation by a liquid or gas

- Unstable condition which requires emergency action, evacuation, or failure

- Unplanned roof or rib fall in active workings that impairs ventilation or impedes passage

- Entrapment for more than 30 minutes or which has a reasonable potential to cause death

- Damage to hoisting equipment in a shaft or slope which endangers an individual or which interferes with use of the equipment for more than 30 minutes

- Coal or rock outburst that causes evacuation or disrupts mining activity for more than 60 minutes

Report A Hazard or Request An Inspection

In addition to reporting emergencies, MSHA’s One Call Does It All number (800-746-1553) can be used for a variety of other non-emergency reasons. You can call to request and inspection, to report a hazardous condition, or file a complaint.

TIP! – Check out our article, “What Is MSHA’s “One Call Does It All”?” for details on MSHA reportable incidents.

23. What is an MSHA Order?

An order is an assertion of a violation issued by an inspector requiring that the mine operator take specific action, often within a specified timeframe or until the violation has been abated. If the mine operator does not comply with an order, the inspector may issue a citation and associated penalty.

24. Can MSHA fine an individual / employee?

Yes, MSHA can fine an individual, typically mine management personnel or anyone considered an “agent of management.” Personal civil penalties can range up to $70K per citation in cases where the company engaged in “aggravated conduct exceeding ordinary negligence.”

Section 110 C of the Mine Act states “Whenever a corporate operator violates a mandatory health or safety standard or knowingly violates or fails or refuses to comply with any order issued under this Act or any order incorporated in a final decision issued under this Act, except an order incorporated in a decision issued under subsection (a) or section 105(c), any director, officer, or agent of such corporation who knowingly authorized, ordered, or carried out such violation, failure, or refusal shall be subject to the same civil penalties, fines, and imprisonment that may be imposed upon a person under subsections (a) and (d).”

25. What is MSHA EPD?

MSHA EPD is the Directorate of Educational Policy and Development, a part of MSHA that oversees education and training programs via planning, monitoring, and evaluation. EPD is in charge of the following activities related to training:

- MSHA enforcement staff training

- Agency policy guidance related to training

- Training material review

EPD also works with other organizations in support of training efforts including:

- Federal and state agencies

- Labor organizations

- Educational institutions

- Mining companies

26. What is MSHA Hazcom?

MSHA’s Hazcom standard was created to protect miners from potentially harmful chemicals in the workplace by providing training, information, labels, and warnings on all chemicals at the mine. The standard requires mine operators to:

- Develop and implement a written HazCom program

- Maintain the written program for as long as a hazardous chemical is known to be at the mine

- Share relevant HazCom information with other on-site operators whose miners can be affected

MSHA’s Title 30 CFR – Hazard Communication (HazCom) standard is intended to:

- Identify the chemicals at the mine

- Determine which chemicals are hazardous

- Establish a HazCom program

- Inform each miner who can be exposed, and other on-site operators whose miners can be exposed, about chemical hazards and appropriate protective measures.

27. What is the MSHA silica standard?

All types of miners can be exposed to airborne respirable silica dust created when crystalline silica is released from quartz minerals during stone crushing, cutting, or breaking activities. Since the body cannot break down silica fibers, the particles become lodged in the lungs and can develop into serious, life-threatening and irreversible lung diseases, including silicosis. However, the health effects of silica dust exposure can take years to develop.

MSHA’s silica standard sets permissible exposure limits (PELs) at 100 micrograms/m3 of air during an 8-hour work shift for miners who may be exposed to respirable silica dust. This is currently twice what OSHA’s silica PEL is for an 8-hour work shift.

In recent years, there have been efforts to lower MSHA’s PEL to be more in line with other agencies, including OSHA and NIOSH (the National Institute for Occupational Safety and Health).

More Questions?

Whew! That’s a load of questions. Got more? Just let us know with a quick message.