In addition to rates of injuries, illnesses, and fatalities, the Mine Safety and Health Administration (MSHA) tracks common mining citations and violations. This information is used to support MSHA’s mission to “prevent death, illness, and injury from mining and promote safe and healthful workplaces for U.S. miners.”

So, what are MSHA’s 20 most commonly cited standards? MSHA’s 20 most commonly cited standards include:

- Accumulation of combustible materials

- Moving machine parts

- Electrical conductors

- Mine ventilation plan; submission and approval

- Safety defects; examination, correction and records

- Preparation and submission of MSHA Form 7000–2—Quarterly Employment and Coal Production Report

- Housekeeping

- Horns and back-up alarms

- Other safeguards

- Protection from falls of roof, face and ribs

- Inspection and cover plates

- Permissible electric face equipment; maintenance

- Electric equipment; examination, testing and maintenance

- Maintenance of incombustible content of rock dust

- Safe access

- Construction and maintenance of guards

- Roof control plan

- Testing grounding systems

- Power wires and cables; insulation and protection

- Loading and haulage equipment

MSHA tracks and uses inspection and enforcement information in several ways to help mine operators avoid the injuries and fatalities associated with these common violations. As a miner, mine operator, or independent mining contractor, the information in this article can potentially save you significant time and reduce or eliminate costly and avoidable citations. These patterns of citations and violations can serve as a guide toward running a safer and more efficient mining operation.

In addition to tracking all cited standards, MSHA created an initiative that highlights commonly cited standards associated with fatal accidents. MSHA’s “Rules to Live By” (RLB) is a series of initiatives that identified and categorized patterns of the conditions and practices that contributed to the most common fatal accidents. With increased attention to these patterns of violations, MSHA’s intention is to “eliminate fatalities in our nation’s mining industry.”

So, with that in mind, we’ll review the most common citations and violations from data collected in 2018 (the latest data available) and briefly review MSHA’s series of Rules to Live By initiatives.

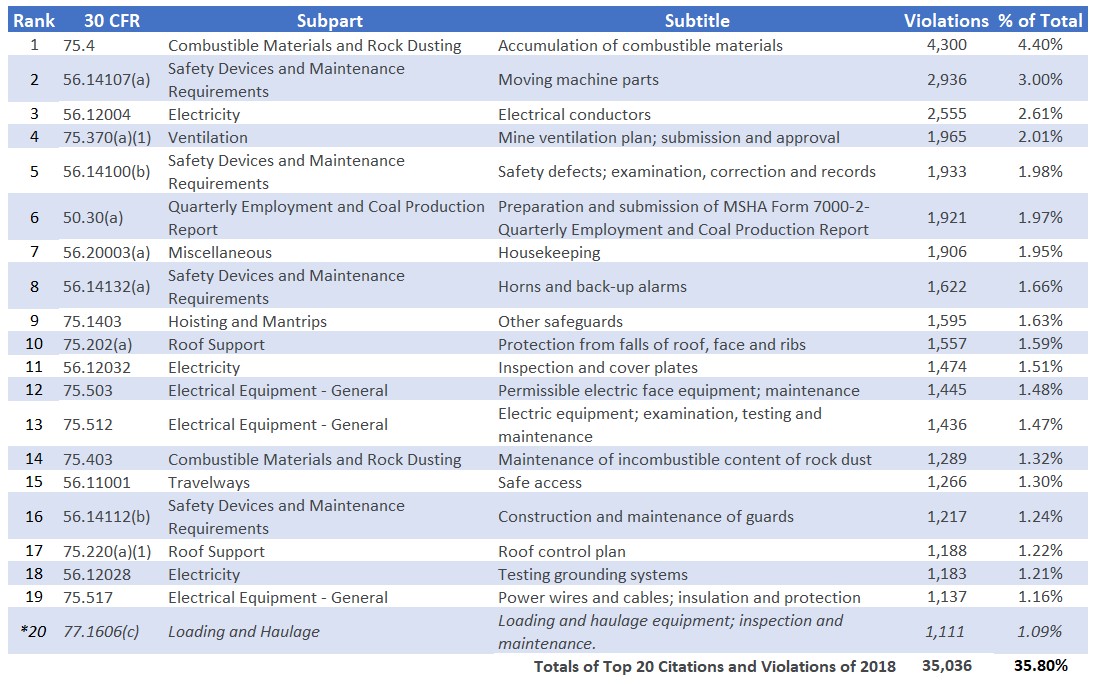

The table below displays the data supplied by MSHA.

TIP! – Be sure to check out our RESOURCES page for a link to MSHA’s “Top 20 Most Frequently Cited Standards by Mine Type” data search tool.

MSHA Inspections, Citations, and Penalty Assessment

MSHA is required by federal regulations to inspect all U.S. mines annually.

- Surface Mines – 2 times per year

- Underground Mine – 4 times per year

During inspections, MSHA may observe and formally document violations of health and safety standards in four basic ways:

- Notices

- Citations

- Orders

- Penalties

MSHA takes several factors into account when assessing a penalty for a citation:

- The mine’s history of previous violations

- Size of the mining business

- Any negligence by the mine operator

- The overall gravity of the violation

- The operator’s good faith in trying to correct the violation promptly

- The effect of the penalty on the operator’s ability to stay in business

Mine operators are afforded the opportunity to contest citations within 30 days of notice of the violation.

The following information is drawn directly from MSHA’s records of cited standards as a result of violations observed during mine inspections.

Accumulation of Combustible Materials

Rank – 1

Violations – 4,300

Percent of Total – 4.4%

Title 30 CFR Part 75.4

“Coal dust, including float coal dust deposited on rock-dusted surfaces, loose coal, and other combustible materials, shall be cleaned up and not be permitted to accumulate in active workings, or on diesel-powered and electric equipment therein.”

Accumulation of coal dust can be extremely hazardous for two main reason:

- It is a respiratory hazard – Accumulated coal dust may indicate that dust abatement and collection are not sufficient or possibly malfunctioning. When coal dust is suspended and when accumulated dust is disturbed and disbursed, it can be inhaled, creating a range of lasting and potentially deadly respiratory problems.

- It is an explosion hazard – Suspended coal dust is an explosion hazard. And accumulated coal dust can ignite and in the event of any other type of explosion. A methane explosion, for example, can ignite the coal dust can increase the intensity of the explosion significantly.

To mitigate the accumulation of coal dust, you should ensure the following procedures and equipment are in place:

- Training – Ensure that workers are trained to recognize potential dust accumulation hazards and keep chute hatches and doors closed.

- Dust collection – Ensure an active dust collection system is in place and functioning properly.

- Machinery Design – Review machine operation and design to ensure that chutes and conveyors are configured in a way to reduce material impact and dust creation.

Moving Machine Parts (Machine Guarding)

Rank – 2

Violations – 2,936

Percent of Total – 3%

Title 30 CFR Part 56.14107

“(a) Moving machine parts shall be guarded to protect persons from contacting gears, sprockets, chains, drive, head, tail, and takeup pulleys, flywheels, couplings, shafts, fan blades, and similar moving parts that can cause injury.

(b) Guards shall not be required where the exposed moving parts are at least seven feet away from walking or working surfaces.”

Moving machine parts represent several hazards that can result in serious injury or even death. Body parts exposed to unguarded machine motions and actions can be:

- Pinched,

- Crushed,

- Severed, or

- Drawn into moving machinery.

Machine motions that may require guarding include:

- Reciprocating

- Rotating

- Transversing

Machine actions that may require guarding include:

- Bending

- Cutting

- Punching

- Shearing

To protect workers from hazardous machine motions and actions, be sure to review all machine guarding requirements and take part in a job hazard analysis (JHA) to identify and mitigate potential hazards.

Electrical Conductors

Rank – 3

Violations – 2,555

Percent of Total – 2.61%

Title 30 CFR Part 56.12004

“Electrical conductors shall be of a sufficient size and current-carrying capacity to ensure that a rise in temperature resulting from normal operations will not damage the insulating materials. Electrical conductors exposed to mechanical damage shall be protected.”

Improperly sized, unprotected, or damaged electrical conductors, breakers, and switches can expose workers to serious risk of shock, electrocution, or deadly arc flash.

Ensure that all electrical work, including installations and repair, is performed by a licensed and experienced electrician and that all work is appropriately permitted and inspected.

Mine Ventilation Plan; Submission And Approval

Rank – 4

Violations – 1,965

Percent of Total – 2.01%

Title 30 CFR Part 75.370(a)(1)

“The operator shall develop and follow a ventilation plan approved by the district manager. The plan shall be designed to control methane and respirable dust and shall be suitable to the conditions and mining system at the mine. The ventilation plan shall consist of two parts, the plan content as prescribed in §75.371 and the ventilation map with information as prescribed in §75.372. Only that portion of the map which contains information required under §75.371 will be subject to approval by the district manager.”

While it’s mandatory to have a mine ventilation plan with an approved map, you can be cited for not adhering to your plan.

Proper ventilation planning and execution is critical to the safety of underground coal miners. Underground mine ventilation performs several important safety functions, including:

- Providing breathable air to miners

- Aiding in dust suppression to protect miners from inhaling hazardous dust particles and reducing the risk of explosion

- Removing toxic and explosive gases, such as methane

Refer to Part 75.371 for an outline of all required elements of a mine ventilation plan.

Safety Defects; Examination, Correction And Records

Rank – 5

Violations – 1,933

Percent of Total – 1.98%

Title 30 CFR Part 56.14100(b)

“Defects on any equipment, machinery, and tools that affect safety shall be corrected in a timely manner to prevent the creation of a hazard to persons.”

Equipment maintenance and repair is critical to safe mining operations. Equipment downtime can be very costly and damaged equipment can be extremely dangerous.

Always ensure that equipment operators are trained to perform pre-operational checks to confirm machinery functions properly. Damaged or malfunctioning machinery must be removed from service until it’s repaired and approved for use.

Adhering to the manufacturer’s maintenance schedule for oil changes, filter replacements, brake linking checks, and all prescribed services will also extend the life of your equipment and reduce the likelihood of mechanical failure.

Preparation And Submission Of MSHA Form 7000–2

Rank – 6

Violations – 1,921

Percent of Total – 1.97%

Title 30 CFR Part 50.30(a)

“Each operator of a mine in which an individual worked during any day of a calendar quarter shall complete a MSHA Form 7000-2 in accordance with the instructions and criteria in §50.30-1 and submit the original to the MSHA Office of Injury and Employment Information, P.O. Box 25367, Denver Federal Center, Denver, Colo. 80225, within 15 days after the end of each calendar quarter.

These forms may be obtained from the MSHA District Office. Each operator shall retain an operator’s copy at the mine office nearest the mine for 5 years after the submission date. You may also submit reports by facsimile, 888-231-5515. To file electronically, follow the instructions on MSHA Internet site, http://www.msha.gov. For assistance in electronic filing, contact the MSHA help desk at 877-778-6055.”

Maintaining and submitting required MSHA documentation and reporting is a necessary part of operating a compliant U.S. mine. MSHA provides all forms and instructions online and district managers and field personnel can offer guidance on how and when to submit documentation.

Use calendar reminders and employ detail-oriented office staff to ensure all forms are filled out correctly and submitted on time to avoid these types of citations.

Housekeeping

Rank – 7

Violations – 1,906

Percent of Total – 1.95%

Title 30 CFR Part 56.20003(a)

“Workplaces, passageways, storerooms, and service rooms shall be kept clean and orderly.”

The state of a mine’s active work areas, storage facilities, maintenance shops, and offices is often a reflection of the culture at the mine. Proper housekeeping can help prevent a wide range of hazards, including:

- Slips, trips, and falls

- Accumulation of combustible materials

- Accumulation of respirable dust

- Being struck by falling objects

- Lacerations and punctures from improperly stored tools

- Potential exposure to hazardous waste

Good housekeeping also saves time and lowers costs while improving safety for everyone in the work area. Tools that are stored properly in consistent locations can be accessed quickly and safely. Walking and working surfaces, stairways, and exits are kept clear, eliminating trip hazards and allowing free movement in case of an emergency.

Simply put, clean and orderly areas are easier to inspect and less likely to be cited for housekeeping violations.

Horns And Back-up Alarms

Rank – 8

Violations – 1,622

Percent of Total – 1.66%

Title 30 CFR Part 56.14132(a)

“Manually-operated horns or other audible warning devices provided on self-propelled mobile equipment as a safety feature shall be maintained in functional condition.”

Your mine should have pedestrian safety policies in place, as well as clearly marked areas in the mine where foot traffic is prohibited. Common pedestrian safety policies include:

- Making eye contact with equipment operators

- Using understood hand signals to communicate intent

- Using radios to coordinate and communicate with equipment operators

- Staying within marked pedestrian travelways

- Always giving equipment the right of way

- Staying out of equipment blind spots – never walking around, and especially behind moving equipment

However, there are often situations where pedestrians inadvertently place themselves in dangerous situations. And as a safeguard, audible horns and backup alarms could potentially save their lives.

Be sure that testing functionality of equipment horns and backup alarms is part of all pre-operational checklists.

Other Safeguards

Rank – 9

Violations – 1,595

Percent of Total – 1.63%

Title 30 CFR Part 75.1403

“Other safeguards adequate, in the judgment of an authorized representative of the Secretary, to minimize hazards with respect to transportation of men and materials shall be provided.”

This standard is specific to safety related to personnel and materials at coal mines. Within subpart, hoisting and “mantrips” (mechanisms designed to transport personnel) safety standards cover a broad range of related equipment, including:

- Hoists

- Communication and signaling systems

- Braking systems

- Self-propelled personnel carriers

- Automatic elevators and cage construction

- Guide ropes

However, this particular standard leaves room for an inspector to use their judgement to issue a citation if additional safeguards may be deemed necessary.

Protection From Falls Of Roof, Face And Ribs

Rank – 10

Violations – 1,557

Percent of Total – 1.59%

Title 30 CFR Part 75.202(a)

“The roof, face and ribs of areas where persons work or travel shall be supported or otherwise controlled to protect persons from hazards related to falls of the roof, face or ribs and coal or rock bursts.”

Managing stability of roof, face, and rib conditions is a perpetual challenge in an active mining environment with constantly changing conditions. However, coal mining operators should stay apprised of the latest roof bolting and rib control management techniques while employing the safest established methods.

Inspection And Cover Plates

Rank – 11

Violations – 1,474

Percent of Total – 1.51%

Title 30 CFR Part 56.12032

“Inspection and cover plates on electrical equipment and junction boxes shall be kept in place at all times except during testing or repairs.”

Covers on electrical equipment are absolutely critical to protect breakers, switches, and electrical components from dust, moisture, impact, or accidental contact with other conductive material.

Always keep panel and junction box covers attached and closed to protect workers from hazardous energy and equipment from potential damage.

Permissible Electric Face Equipment; Maintenance

Rank – 12

Violations – 1,445

Percent of Total – 1.48%

Title 30 CFR Part 75.503

“The operator of each coal mine shall maintain in permissible condition all electric face equipment required by §§75.500, 75.501, 75.504 to be permissible which is taken into or used inby the last open crosscut of any such mine.”

Be sure that your mine has an active and effective maintenance program that keeps all equipment in permissible condition.

Permissible condition represents different parameters of operation and function depending upon the type of equipment. If you’re responsible for operating equipment, be sure to perform pre-operational inspections and understand what permissible condition means for that type of equipment.

Electric Equipment; Examination, Testing And Maintenance

Rank – 13

Violations – 1,436

Percent of Total – 1.47%

Title 30 CFR Part 75.512

“All electric equipment shall be frequently examined, tested, and properly maintained by a qualified person to assure safe operating conditions. When a potentially dangerous condition is found on electric equipment, such equipment shall be removed from service until such condition is corrected. A record of such examinations shall be kept and made available to an authorized representative of the Secretary and to the miners in such mine.”

Proper maintenance and testing of equipment by trained professionals save time and money.

Be sure your mine has an active and effective maintenance program that’s supported by use of pre-operational equipment inspections. When you have questions about the condition or safe operation of a piece of equipment, you should bring that to the attention of your supervisor or maintenance personnel to address the concerns immediately and prior to operating the machinery.

Maintenance Of Incombustible Content Of Rock Dust

Rank – 14

Violations – 1,289

Percent of Total – 1.32%

Title 30 CFR Part 75.403

“Where rock dust is required to be applied, it shall be distributed upon the top, floor, and sides of all underground areas of a coal mine and maintained in such quantities that the incombustible content of the combined coal dust, rock dust, and other dust shall be not less than 80 percent. Where methane is present in any ventilating current, the percent of incombustible content of such combined dust shall be increased 0.4 percent for each 0.1 percent of methane.”

Limestone dust is commonly used as a non-combustible barrier applied to exposed coal mine surfaces (roof, face, ribs, and floors) to reduce the risk of coal combustion and potential explosions.

Because the non-combustible limestone rock dust is intended to prevent explosions, the percentage of non-combustible material in the dust must be high enough to counteract the combustibility of the coal surfaces, any accumulated coal dust, and any methane that may be present.

Safe Access

Rank – 15

Violations – 1,266

Percent of Total – 1.30%

Title 30 CFR Part 56.11001

“Safe means of access shall be provided and maintained to all working places.”

All travelways to and from working areas must be clear and allow safe access for workers.

General housekeeping principles should be used to prevent common hazards from clutter and ensure safe access to and from work areas.

Construction And Maintenance Of Guards

Rank – 16

Violations – 1,217

Percent of Total – 1.24%

Title 30 CFR Part 56.14112(b)

“Guards shall be securely in place while machinery is being operated, except when testing or making adjustments which cannot be performed without removal of the guard.”

Machine guarding protects workers from potentially hazardous machine motions and actions. All required machine guards should be checked during each shift and repaired or replaced as needed. Guards should be replaced after performing any work that requires their removal.

You should never remove a guard while a machine is operating. De-energize the equipment and follow all lockout-tagout procedures when work on unguarded machine components is necessary.

Roof Control Plan

Rank – 17

Violations – 1,188

Percent of Total – 1.22%

Title 30 CFR Part 75.220(a)(1)

“Each mine operator shall develop and follow a roof control plan, approved by the District Manager, that is suitable to the prevailing geological conditions, and the mining system to be used at the mine. Additional measures shall be taken to protect persons if unusual hazards are encountered.”

Planning and managing roof conditions is a key element of coal mining safety. Use of scaling methods, supports, and roof bolting are common methods of roof control for continuous coal mining.

Your mine’s roof control plan should provide details of the methods used. Miners and miners’ representatives have the right to review a copy of the mine’s roof control plan.

Testing Grounding Systems

Rank – 18

Violations – 1,183

Percent of Total – 1.21%

Title 30 CFR Part 56.12028

“Continuity and resistance of grounding systems shall be tested immediately after installation, repair, and modification; and annually thereafter. A record of the resistance measured during the most recent tests shall be made available on a request by the Secretary or his duly authorized representative.”

Tests of grounding systems should be done by a licensed electrician. All records of system installation, repair, and testing should be kept and made available to MSHA inspectors.

Power Wires And Cables: Insulation And Protection

Rank – 19

Violations – 1,137

Percent of Total – 1.16%

Title 30 CFR Part 75.517

“Power wires and cables, except trolley wires, trolley feeder wires, and bare signal wires, shall be insulated adequately and fully protected.”

Exposure to bare electrical wires can cause severe electrical shock and even death. It can also be hazardous to the equipment, causing a short, damaging components, and losing time for costly repairs.

Inspect all equipment each shift, including electrical wiring and components to eliminate risk of shock or equipment damage. If wiring insulation is cracked, worn, or missing, have an authorized electrician repair or replace the wiring immediately.

Loading And Haulage Equipment

Rank – *20

Violations – 1,111

Percent of Total – *1.09%

Title 30 CFR Part 77.1606(c)

“Equipment defects affecting safety shall be corrected before the equipment is used.”

This is another example of the value of pre-operational checks to ensure that equipment is in safe, functional condition. When damaged or malfunctioning parts are observed, leaking fluid is visible, unexpected smoke or steam appears, or machine functions don’t sound normal, remove the equipment from operation and have an authorized mechanic evaluate the situation.

The equipment should only be returned to operational use when all repairs and maintenance have been completed and the unit functions properly and safely after testing.

*NOTE – Since the 15th most commonly cited standard in MSHA’s report displays a “0” referencing the standard and no entry for the subtitle, it’s impossible to identify exactly what standard was cited. Therefore, item number 20 was added with an estimated ranking and percentage of the total based on additional research into standards cited for Part 46 and Part 48 mines.

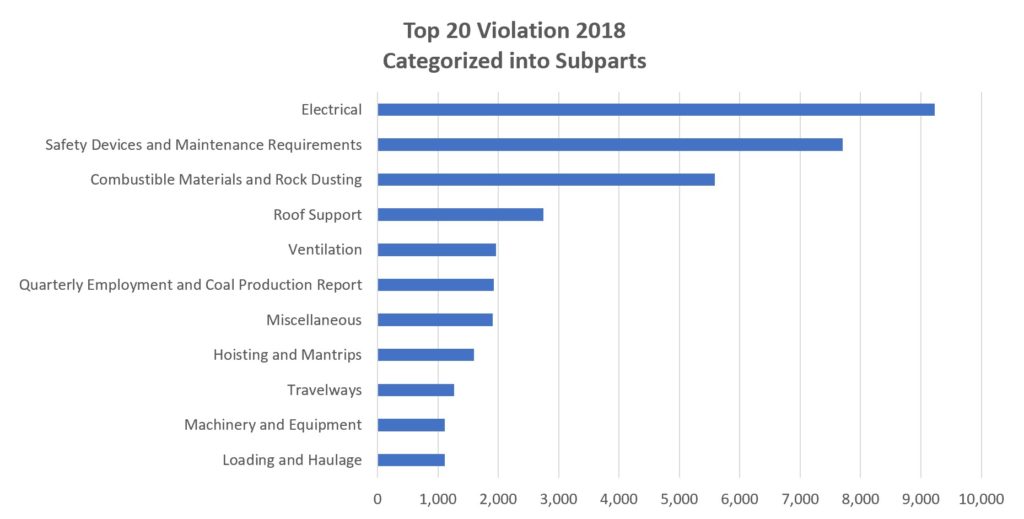

Commonly Cited Standards By Subpart

Another way to view these commonly cited standards is by rolling them into their associated “subparts” within CFR 30. So, we’ve done that for you, revealing that these top 3 types of citations account for 62% of the 20 most commonly cited standards:

- 26% – Electrical

- 21% – Safety Devices and Maintenance Requirements

- 16% – Combustible Materials and Rock Dusting

Rules To Live By (RLB)

MSHA’s “Rules to Live By” (RLB) is a series of initiatives that began in 2010 with the goal of preventing mining fatalities. The main idea is to focus on the most cited accidents and causes of mine fatalities to inform and prevent injury and death.

While MSHA used statistics on the most cited standards as the basis for the RLB initiative, that actual standards have been grouped into categories of fatal accident root cause types. So, with a focus on citations related to fatalities, the resulting categories will appear different than the overall listing of total citations, many of which were not related to fatal accidents.

The initial RLB campaign in 2010 set the stage for two successive campaigns that expanded the fatal accident categories intended to increase awareness and training to reduce fatalities.

Rules to Live By I – Fatality Prevention – focused on 24 frequently cited standards in 9 accident categories:

- Falls from Elevation

- Falls of Roof and Rib

- Operating Mobile Equipment (Surface)

- Operating Mobile Equipment (Underground)

- Maintenance

- Lock and Tag Out

- Struck by Mobile Equipment (Surface)

- Struck by Mobile Equipment (Underground)

- Blocking Against Motion

Rules to Live By II – Preventing Catastrophic Accidents – focused on 9 standards cited due to mine disasters in 4 accident categories:

- Mining Methods

- Explosions

- Aftermath of a Fire

- Exams

Rules to Live By III – Preventing Common Mining Deaths – focuses on 14 standards due to recent mining fatalities.

Through the RLB outreach program, MSHA provides mine operators and miners’ representatives a range of information, reports, posters, training materials, and other resources to support efforts to improve workplace safety.

Related Questions

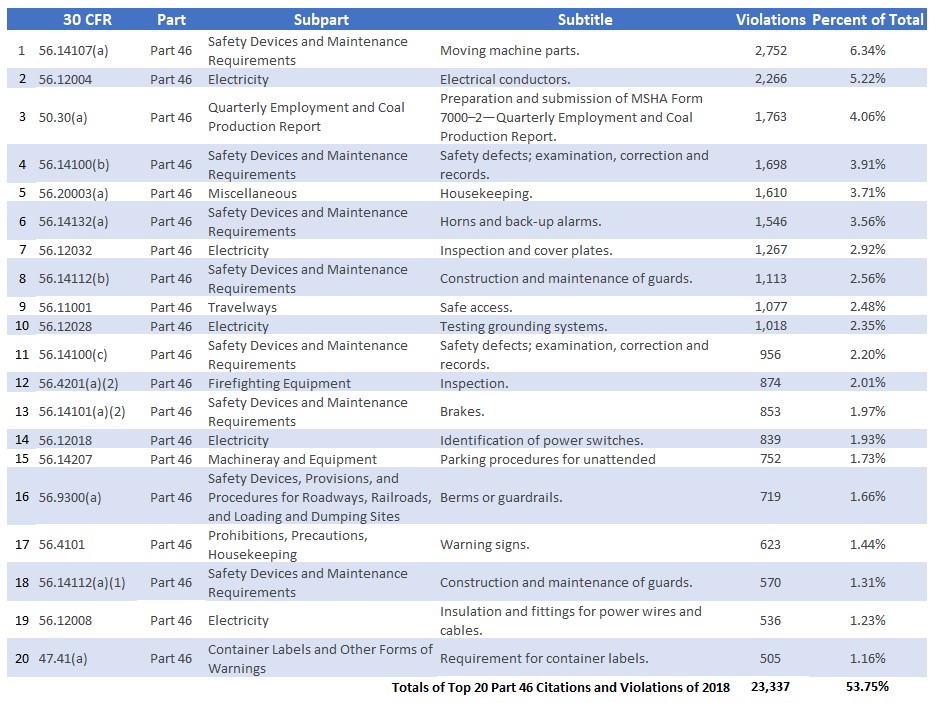

What are the 20 most commonly cited standards for surface mining (Part 46)?

This chart illustrates the 20 most commonly cited standards for surface mines in 2018.

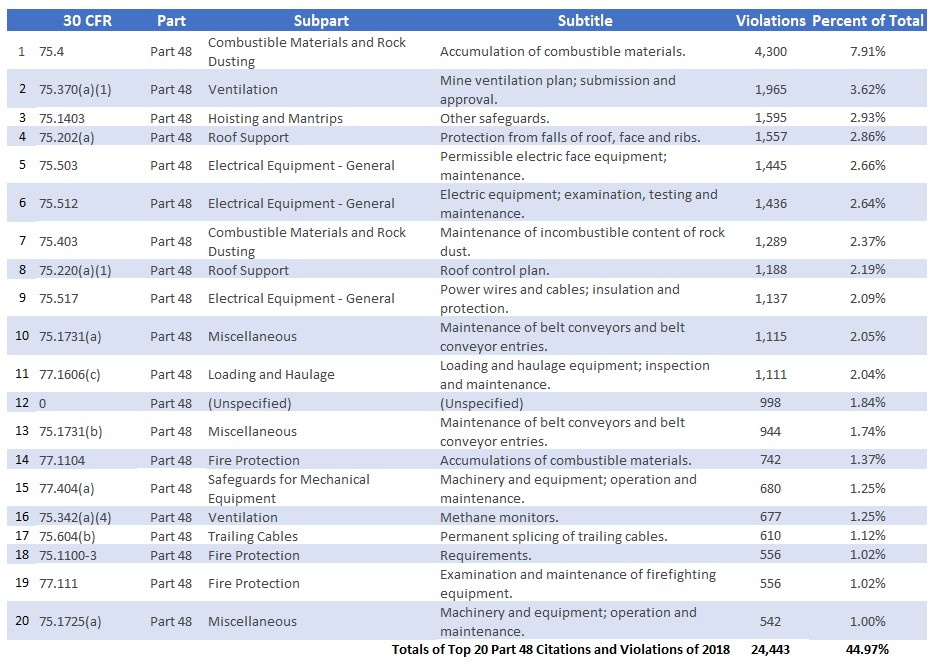

What are the 20 most commonly cited standards for underground mining (Part 48)?

This chart illustrates the 20 most commonly cited standards for underground mines in 2018.