Occupational noise is one of the most common health hazards in mining. While noise induced hearing loss (NIHL) is an obvious outcome, workers exposed to high levels of occupational noise for extended periods of time can suffer from heightened stress, auditory sensitivity, tinnitus, and other conditions that can severely impact their quality of life. Since the effects of hearing loss can be irreversible, MSHA created a hearing conservation program (HCP) to protect miners working in environments where the noise exceeds certain levels.

So, what is MSHA’s hearing conservation program? MSHA’s hearing conservation program is based on Part 62 of Title 30 in the Code of Federal Regulations outlining requirements for protecting miners from occupational noise exposure. An MSHA-compliant hearing conservation program involves:

- Assessing and Monitoring Noise Exposure

- Providing Audiometric Testing

- Recordkeeping of Audiometric Test Results

- Providing and Ensuring Use of Hearing Protectors

- Training on the Purpose, Use, and Value of Hearing Protectors

MSHA’s hearing conservation program is a federally required part of miner safety. Understanding these health and safety standards, the hazards associated with work environments, and the protective measures that can be taken to avoid harmful effects are critically valuable whether you’re a mine operator, a miner, or a mining contractor. The information in this article could potentially ensure that you or a coworker keep your ability to hear for many years to come.

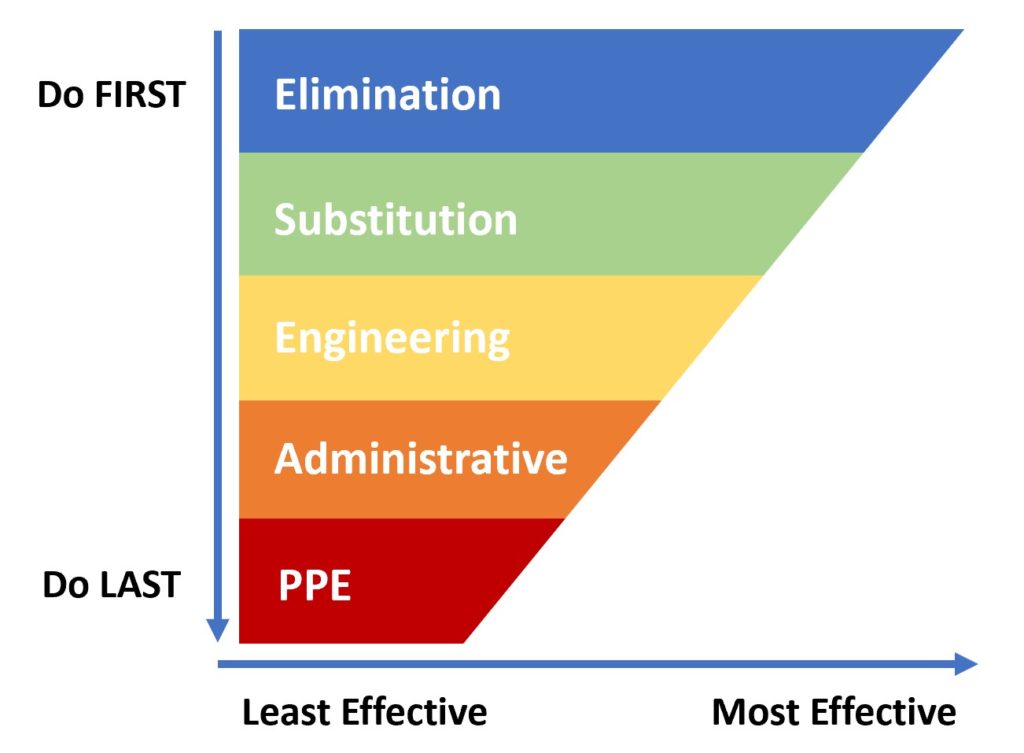

The Hierarchy of Controls

It’s generally understood that personal protective equipment (PPE) is a last line of defense for protection from workplace hazards. And work at a mine is no different. Before jumping into the details of audiometric testing and permissible exposure limits related to MSHA’s hearing conservation program, it’s important to understand that there is a hierarchy of protective measures that must be explored to reduce a miner’s exposure to hazardous noise:

- Hazard Elimination – Removes the hazard

- Substitution – Replaces with lesser hazard

- Engineering Controls – Isolates or reduces the hazard

- Administrative Controls – Changes how people work around the hazard

- Personal Protective Equipment (PPE) – Protects people from direct exposure to the hazard

Hazard Elimination – Whenever possible, the hazard should ideally be removed from the workplace. Mining operations need continuous, large-scale power. And where there’s heavy equipment, large electric motors, massive conveyors, and huge diesel engines, there will be noise. So, completely eliminating mine noise is not always feasible.

Substitution – Substitution, or simply replacing items with less hazardous alternatives, is much easier in the early stages of workplace planning and design. A less hazardous chemical or piece of equipment that accomplishes an equivalent output may be substituted for one that could require more downstream controls or PPE, increasing risk and costs. As mining equipment technology advances, motors tend to get more powerful, smaller, and quieter. When equipment wears out, it’s always wise to explore what options are available for low-noise tools and equipment.

Engineering Controls – These are physical methods of applying barriers or equipment design principles to reduce the intensity of potentially hazardous noise at the source.

One of the most common engineering controls is to place a barrier of some kind between the hazard and the worker. For machine motion or action hazards, the engineering control is often in the form of guarding. Metal screens, plates, or plexiglass are often used to eliminate the risk of appendages being pinched, crushed, or drawn into machinery.

Engineering controls used to reduce occupational noise include:

- Enclosed machine housings that isolate and dampen noise

- Advanced engine mufflers

- Sound absorbing barriers and curtains

Administrative Controls – These are alternative work procedures that may reduce a miner’s noise exposure duration, frequency, or intensity. Administrative controls may include:

- Changing worker schedules during times when fewer loud machines operate

- Placing workers farther away from the noise source

- Shortening shifts for workers exposed to high noise levels

PPE – This encompasses a broad range of equipment and devices worn by a miner to protect from physical, chemical, and environmental hazards. In the context of occupational noise, this involves the use of ear plugs, earmuffs, or both. Using both is considered “dual hearing protection.”

- Ear plugs

- Earmuffs

- Dual Hearing Protection (using both ear plugs and earmuffs)

Working through each of these steps is an accepted method of effectively protecting miners from occupational noise.

Assessing and Monitoring Noise Exposure (Part 62.110)

MSHA requires that mine operators “establish a system of monitoring that evaluates each miner’s noise exposure sufficiently to determine continuing compliance with this part.” This effectively means that the work environment must be tested in two basic ways to see how much noise a miner will be exposed to during a normal 8-hour shift:

- Workplace sound level measurement – A sound level meter is used to sample workplace noise levels.

- Worker noise dose assessment – A dosimeter is worn by a miner during an entire shift to assess a miner’s “dose” of noise exposure, the time-weighted-average of noise over a typical 8-hour work period (TWA8).

Sound level is measured in “decibels,” increments of sound pressure levels, to determine the amount of occupational noise.

MSHA requires that the dose be determined:

- Without adjusting for the use of hearing protection

- With integration of all sound levels over the appropriate range

- As a reflection of the miner’s full work shift

- By using a 90-dB criterion level and a 5-dB exchange rate

- By using the A-weighting and slow response instrument settings on the sound measurement devices

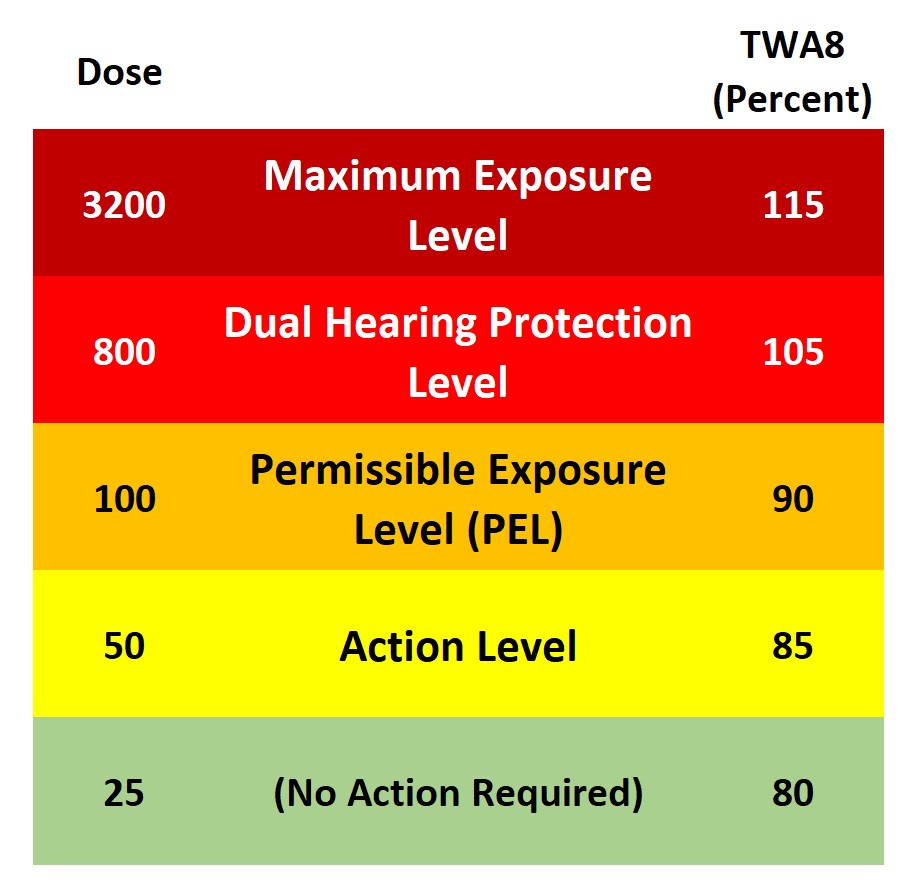

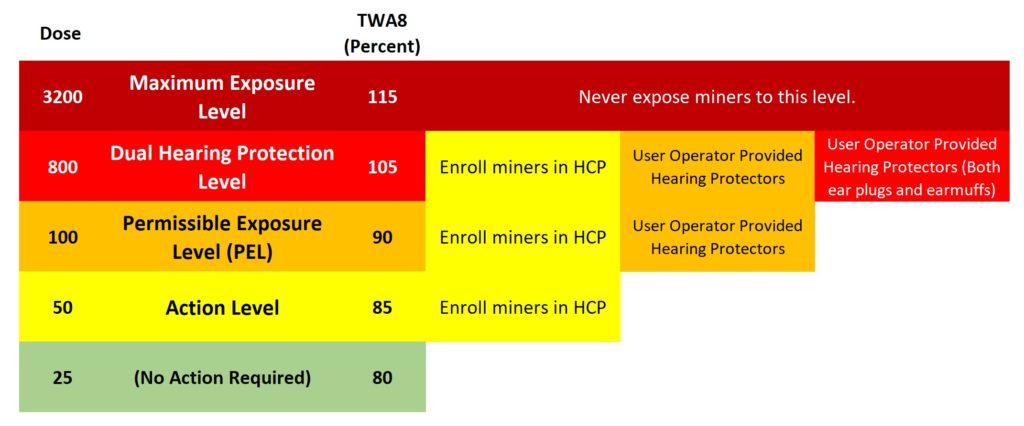

Noise Exposure Levels

MSHA specifies actions to be taken at 3 defined levels of occupational noise. These levels are determined by the results of a compliant noise assessment and are defined as:

- The Action Level – (at 85 dB) Mine operator must enroll miners exposed to noise at or above this level in an HCP.

- The Permissible Exposure Level – (at 90 dB) Mine operators must continue to use engineering and administrative controls and provide hearing protectors.

- The Dual Hearing Protection Level – (at 105 dB) Mine operator ensures concurrent use of both ear plugs and earmuffs.

Within 15 calendar days of the exposure determination and corrective actions, affected miners and their representatives have the right to:

- Be informed of noise exposure equal to or in excess of the action level, permissible exposure level, or the dual hearing protection level

- Be provided prior notice of the date and time of exposure monitoring

- Observe noise exposure monitoring activities

Both the workplace sound level measurement and the assessed daily dose of noise exposure may be used to make decisions about equipment design and the work environment conditions starting at the top of the hierarchy of controls. These measures will also ultimately determine if and how much hearing protection may be required for each miner.

Using Table 62-2 provided in the Part 62 Appendix, mine operators must convert the dose readings to equivalent TWA8 to determine what level of action must be taken with regard to hearing protection.

Providing Audiometric Testing (Part 62.170)

MSHA requires that mine operators “provide audiometric tests … at no cost to the miner. A physician or an audiologist, or a qualified technician under the direction or supervision of a physician or an audiologist must conduct the tests.”

Within 6 months of being enrolled in an HCP, each miner must be provided with an audiogram (hearing test) to determine their baseline hearing sensitivity. This baseline audiogram established each miner’s hearing level to compare against required annual audiograms to see if any change to the miner’s hearing has occurred.

Prior to the baseline audiogram, the mine operator is required to notify each miner to avoid high noise levels for a minimum of 14 hours, ensuring that the miner’s hearing hasn’t been temporarily affected by noise before the test. The mine operator may either enforce the 14-hour quiet period by not exposing the miner to workplace noise or have the miner wear sufficient hearing protection in preparation for the baseline audiogram.

If annual audiograms indicate either a permanent standard threshold shift or an improvement over the baseline audiogram, then the annual audiogram results must be deemed a “revised baseline audiogram” for testing comparisons moving forward.

Audiometric Testing Procedures (Part 62.171)

MSHA outlines specific requirements for audiometric testing “in accordance with scientifically validated procedures.” To meet MSHA’s requirements, audiometric testing must be conducted to determine hearing thresholds by qualified personnel using:

- Pure Tone – Use of a standard, universally accepted set of tones or beeps

- Air Conduction – Method of determining sound perception from your outer ear through your middle ear

- Test Frequencies of 500, 1000, 2000, 3000, 4000, and 6000 Hz

- Tests for Each Ear Separately

Evaluation of Audiograms (Part 62.172)

MSHA requires that evaluation of audiograms be performed by a physician, audiologist, or qualified technician to determine:

- If the test is valid

- If a change in hearing threshold has occurred

The miner operator must obtain the results and interpretations of audiograms within 30 days of testing.

Any findings not associated with hearing loss may not be revealed to the mine operator without the written consent of the miner.

If the test is determined to be either invalid or reveals a reportable hearing loss, audiometric testing must be repeated within 30 calendar days.

However, if the test reveals a threshold shift or hearing loss, MSHA provides age correction values in Tables 62-3 and 62-4 in the Part 62 Appendix to account for an individual’s aging as a contributing factor to hearing loss.

Follow-up Evaluation for Invalid Audiograms (Part 62.173)

The qualified person performing the audiogram may refer the miner for a clinical audiological evaluation or an otological examination (by an ear, nose, and throat doctor) if a valid audiogram cannot be obtained due to medical pathology either:

- Caused or aggravated by occupational noise exposure or wearing of hearing protection, or

- Unrelated to occupational noise exposure or wearing of hearing protection.

The mine operator must inform the physician performing the otological examination that any results unrelated to occupational noise exposure must not be revealed to the mine operator without the miner’s written consent.

Corrective Measure (Part 62.174)

Within 30 days of receiving confirmation of a miner’s hearing loss, MSHA requires that the mine operator:

- Review the effectiveness of its hierarchy of controls (i.e. engineering and administrative controls) and take corrective actions as needed

- Provide the miner with the opportunity to select different hearing protection

- Retrain the miner on the effects of noise on hearing and the purpose and value of wearing hearing protection

Recordkeeping of Audiometric Test Results (Part 62.190)

MSHA requires that miner operators compile “compile an audiometric test record for each miner tested” that includes 5 specific pieces of information:

- Miner Name and Job – Name and job classification of the miner tested

- All Prior Audiograms – A copy of all of the miner’s audiograms

- Validation Procedures – Evidence that the audiograms were conducted in accordance scientifically validated procedures

- Noise Exposure Assessment Results – Any exposure determination for the miner

- Successive Testing Results – The results of follow-up examination(s), if any

Audiometric test records must be maintained for the duration of each enrolled miner’s employment and for a minimum of 6 months after the miner is no longer employed at the mine.

Mine operators must also maintain a copy of noise exposure determinations and corrective actions to be taken.

All records must be made available to:

- MSHA inspectors,

- Authorized representatives of the U.S. Department of Labor, and

- Persons evaluating the audiograms.

And within 15 calendar days of written requests, access to records must be provided to:

- The miner or the miner’s designee (with written consent)

- The miners’ representative, and

- Any former miner.

If a physical copy of records is requested, the first copy must be provided at no cost to the personnel in the above list.

If the mine changes ownership, all records must be transferred to the successor mine operator, who will use the baseline or revised baseline audiograms for further required testing.

Providing and Ensuring Use of Hearing Protectors (Part 62.160)

MSHA requires that mine operators provide hearing protection and associated training to miners who are exposed to occupational noise levels that exceed the “action level” during their work period. Again, hearing protection in the form of ear plugs and earmuffs is considered the last line of defense after all other protective measures have been taken to remove, substitute, engineer, or change behavior related to the hazard.

The miner must be allowed to choose from at least 2 types of ear plugs and earmuffs at no cost to the miner.

Mine operators must ensure that all protective equipment is in good, functional condition, properly fitted to the miner, maintained to manufacturer specifications, and worn whenever exposure exceeds the “action level.”

Training on the Purpose, Use, and Value of Hearing Protectors (Part 62.180)

MSHA requires that mine operators provide training hearing protector training within 30 calendar days of enrolling a miner into an HCP. This training must cover subjects that include:

- The effect of occupational noise on hearing

- The purpose and value of wearing hearing protectors (ear plugs, earmuffs, or both)

- The advantages and disadvantages of hearing protectors provided by the mine operator

- Specifics on the fitting, use, care, and maintenance of hearing protectors provided by the mine operator

- The roles, responsibilities, and tasks of the mine operator and miner related to hearing protection and testing

- The purpose, value, methods, and schedules of audiometric testing and access to test results

Training must be provided every 12 months after initial training for miners who continue to work in areas where the noise level is equal or greater than the action level.

MSHA requires that mine operators record and certify the date and type of training provided to miners and retain the miner’s most recent training records for:

- The duration of the miner’s enrollment in the HCP

- At least 6 months after the miner is either no longer in the HCP or no longer employed at the mine

Related Questions

What personal protective equipment (PPE) does MSHA require?

MSHA requires a broad range of PPE and other safety equipment for surface miners, underground miners, and miners working on or near water. Examples of PPE that MSHA requires based on federal regulations include:

- Hard hats

- Eye protection from general injury and grinding wheel

- Hearing protection

- Respiratory devices and self-contained self-rescue (SCSR) equipment

- Hand protection

- Protective clothing from irritants and hot work

- High visibility vests and clothing

- Life jackets and belts

- Safety belts and lines

- Protective footwear

- Flashlights and headlamps

- First aid material

For more on MSHA PPE requirements and examples of PPE that miners typically use, check out our article, “Personal Protective Equipment For Mining – PPE Product Guide.”

What is MSHA’s HazCom Standard?

MSHA’s HazCom standard is a set of regulatory requirements intended to reduce injuries and illnesses by ensuring that each mine operator –

- Identifies the chemicals at a mine,

- Determines which chemicals are hazardous,

- Establishes a hazard communication (HazCom) program, and

- Informs each miner and worker on-site who can be exposed about chemical hazards and appropriate protective measures.

For more on MSHA’s HazCom standard, check out our article, “What Is MSHA’s HazCom And How Is It Different From GHS?”

What are the most common health risks associated with mining?

The 10 most common health risks to miners include:

- Respirable Dust

- Equipment Exhaust

- Noise

- Fatigue

- Thermal Stress

- Mental Stress

- Musculoskeletal Disorder

- Vibration

- UV Exposure

- Chemical Exposure

For more on the most common health risks that miners face, check out our article, “10 Long-Term Mining Health Risks And How To Protect Yourself.”