When I started researching and writing my first mining safety eLearning courses that would ultimately become many hours of MSHA Part 46 New Miner Training, the task was beyond daunting. I quickly found myself drowning in the Part 46 regulations and all the supporting documents that are intended to interpret and explain how it all works. I wasn’t a miner. Or a lawyer… I was overwhelmed.

Overwhelmed… That’s exactly how I’d describe the mining contractors who would later call me for advice. By simply bidding on a project at a surface mine, they’d suddenly launched themselves into an entirely new world of documentation requirements, compliance expectations, and training costs. They were too stunned and buried under the weight of it all to even know what questions to start with.

If that sounds like you, you’re in luck. I created this guide to help you sift through all the governmental legal-speak and get down to what you need to do to comply with MSHA Part 46 New Miner Training requirements.

So, what’s in the MSHA Part 46 For Contractors – Your Ultimate Compliance Guide? Here’s an outline of what you’ll find inside:

- Getting Started

- Part 46 or Part 48?

- Miner or Contractor – What’s the Difference?

- Getting an MSHA ID

- Part 46 Compliant Documentation

- Part 46 Training Plan

- Part 46 Record of Training

- Part 46 Training Requirements for Contractors

- New Miner Training

- Annual Refresher Training

- How to Handle an Inspection

- Training Options for Contractors

- Entering a Mine Site

Keep in mind that getting through all the required training and documentation will take time. It’ll also cost some money. And it’s a bit of a headache. But to get the contract for work at a surface mine, there’s just no way around it. And getting compliant and staying compliant will save you even bigger headaches and potentially costly fines down the road.

So, slow down for a moment. Take a deep breath. And let’s get to work.

1 – Getting Started

The very best place to start is right here. I’ll get you an overview of what it means to be a contractor suddenly responsible for complying with MSHA Part 46 Training regulations. I’ll walk you through the regulations so it’s clear –

- what you need to do,

- when you need to have it done, and

- how it needs to be done in compliance with MSHA.

Throughout this guide, I’ll reference two key documents:

- Title 30 CFR (Code of Federal Regulations) – Part 46

- Interpretations and Guidelines on Enforcement of the 1977 (Mine) Act

Links to both of these documents can be found on our RESOURCES page. It’s a really good idea to get familiar with both the official regulations and MSHA’s own interpretations and guidelines. Once you go through them a couple of times, they’re not so bad.

I just know from personal experience, that starting with those documents without some guidance can lead to a huge steaming pile of frustration. Then you’re right back to looking for help.

So, you’ve started in the right place. I’m here to help.

TIP! – Go to our RESOURCES for links to Title 30 CFR – Part 46 and the Interpretations and Guidelines on Enforcement of the 1977 (Mine) Act.

2 – Part 46 or Part 48?

When a contractor calls for advice, the first question I ask is – Will your team be working at a Part 46 or Part 48 mine? It’s not uncommon for a contractor new to the mining industry to not have any idea. It’s just a mine! What’s the difference?

The answer to the Part 46 or Part 48 question will determine very different paths toward getting compliant training, and ultimately getting the contract to work at the mine. This is because the differences in how MSHA enforces the two regulations are vast. In short, here are the key differences:

- Part 46 – Surface mines (non-metal, non-coal, stone, sand and gravel) – 24 hours of New Miner Training and documentation can be entirely managed by you. No need to submit anything to MSHA for approval.

- Part 48 – Underground and surface areas of underground mines (metal, coal, minerals, precious stones) – 40 hours of New Miner Training that must be conducted by an MSHA-approved Part 48 trainer. Training Plans must be submitted to MSHA for approval.

The best way to confirm which type of mine you’re planning to work at is to ask the mine. They will know for sure which regulations they’re subject to.

Go ask. I’ll wait…

Got your answer? Good – If it’s Part 46, GREAT! We can keep rolling along.

If it’s Part 48, this document will not be your ideal resource for moving forward. Your best path toward compliance with Part 48 training requirements is to talk with the mine to see if they’re open to including your team in any New Miner training they may have scheduled. You can also contact MSHA directly for suggestions on their State Grant resources for Part 48 trainers in your area.

But even though Part 48 represents a longer, stricter, and more costly path, there’s an upside. When your team completes Part 48 Underground training, they are automatically covered for access to any Part 46 Surface mine. So, you don’t have to send them to Part 46 Surface miner training. Bonus!

OK, Part 46’ers only now… Let’s forge ahead.

3 – Miner or Contractor – What’s the Difference?

It’s really common for contractors to start this process with the idea that they are not miners, so they should not be expected to have all the same training as miners. They should get a pass, an allowance for some scaled-down version of training. That would be great. But that’s not how it works.

MSHA keeps it very simple – Contractors are expected to adhere to ALL the same training and documentation requirements as miners. Period. *Gulp*

That’s a big, jagged pill to swallow. But that’s how the federal regulation works. And mine operators who are liable for what happens at their mines won’t allow contractors who aren’t compliant to perform work on-site.

But let’s make sure everyone’s on the same page regarding who’s a miner and who’s a contractor.

MSHA defines a miner as –

- “any person, including any operator or supervisor, who works at a mine and who is engaged in mining operations. This definition includes independent contractors and employees of independent contractors who are engaged in mining operations; and (ii) Any construction worker who is exposed to hazards of mining operations.”

MSHA defines an independent contractor as –

- “any person, partnership, corporation, subsidiary of a corporation, firm, association or other organization that contracts to perform services or construction at a mine… [and are] exposed to mine hazards for frequent or extended periods.”

- “Frequent” exposure is defined as a pattern of exposure to hazards at mining operations occurring intermittently and repeatedly over time.

- “Extended” exposure means exposure to hazards at mining operations of more than five (5) consecutive work days.

So, Part 46 outlines the identical training required for both miners and mining contractors. We’ll go through those training requirements in more detail in the New Miner and Annual Refresher Training sections.

4 – Getting an MSHA ID

While MSHA doesn’t require that independent contractors get an MSHA ID for Part 46, you can apply online to get one at no cost.

There’s a place on all forms and documents for your MSHA ID, so it’s a really good idea to just apply for one so that all your information is in order.

It’s also a really good idea to get one in the event that you ever transition to work at Part 48 mines, which require independent contractors to have MSHA IDs. So, you’ll be one step ahead!

TIP! – Go to our RESOURCES for a link to the MSHA Forms & Online Filing page, where you’ll find a link to the 7000-52 Contractor ID Request Form.

5 – Compliant Documentation

There are two types of documents that MSHA requires you to create and maintain for Part 46 training.

- Training Plan – The requirements for this document are found in Part 46.3 – Training Plans.

“You must develop and implement a written plan… that contains effective programs for training new miners…, training miners for new tasks, annual refresher training, and site-specific hazard awareness training.”

- Record of Training – The requirements for this document are found in Part 46.9 – Record of Training.

“You must record and certify on MSHA Form 5000-23, or on a form that contains the information listed in paragraph (b) of this section, that each miner has received training required under this part.”

I’ve often described this as the “MSHA document sandwich” with the training in the middle. You’ll start with the Training Plan, conduct the training, then document that the training has been completed with a Record of Training for each individual trainee.

These are the documents that MSHA will ask to see if you’re ever inspected. While you can definitely keep your documents electronically, MSHA recommends that you keep hard copies available.

TIP! – Go to our RESOURCES page for a link to MSHA’s Educational Field and Small Mine Services department. They offer downloadable Training Plan and Record of Training templates.

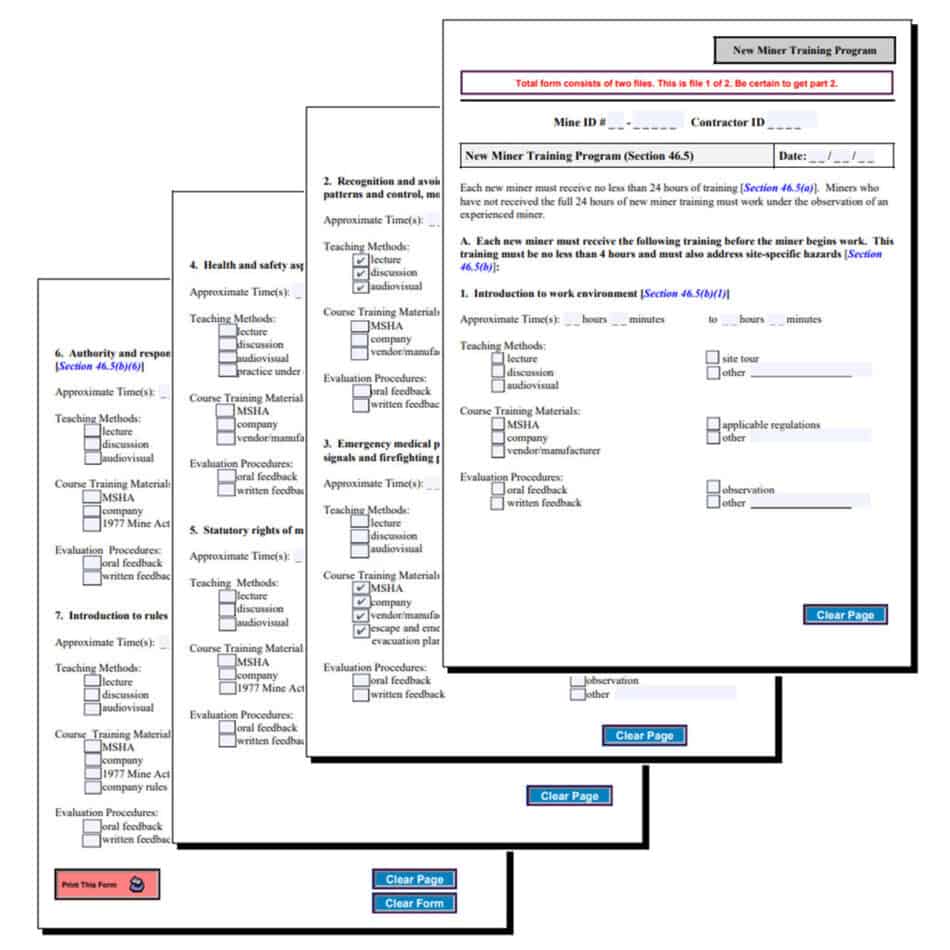

6 – Part 46 Training Plan

MSHA specifically outlines each item of information required to develop a compliant Training Plan. For Part 46, your training plan is considered approved by MSHA if it contains, at a minimum, the following information:

“(1) The name of the production-operator or independent contractor, mine name(s), and MSHA mine identification number(s) or independent contractor identification number(s);

(2) The name and position of the person designated by you who is responsible for the health and safety training at the mine. This person may be the production-operator or independent contractor;

(3) A general description of the teaching methods and the course materials that are to be used in the training program, including the subject areas to be covered and the approximate time or range of time to be spent on each subject area.

(4) A list of the persons and/or organizations who will provide the training, and the subject areas in which each person and/or organization is competent to instruct; and

(5) The evaluation procedures used to determine the effectiveness of training.”

TIP! – Go to our RESOURCES page for a link to MSHA’s Educational Field and Small Mine Services department. They offer downloadable Training Plan and Record of Training templates.

7 – Part 46 Training Record of Training

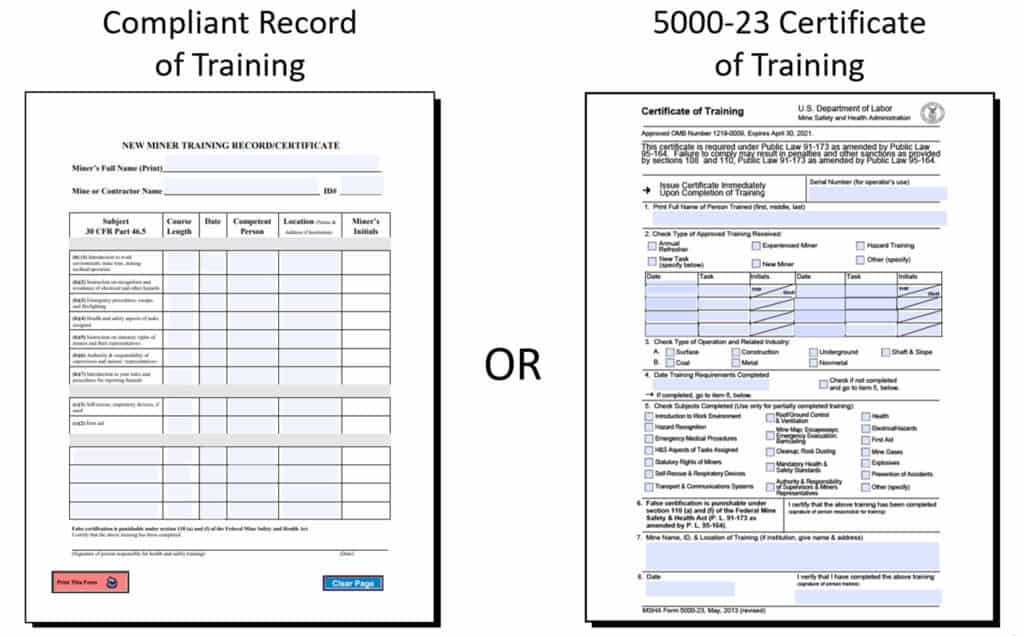

In Part 46.9 – Records of Training, MSHA gives you two options for maintaining compliant Records of Training.

5000-23 Certificate of Training – This is the standard form used by most mines and mining contractors. It was originally designed for Part 48 training use, so it’s actually formatted with some different information than MSHA requires for a compliant Part 46 Record of Training. Regardless, it’s what most people use.

Record of Training – This is a document that MSHA considers compliant if it contains the following information:

“(1) The printed full name of the person trained;

(2) The type of training, the duration of the training, the date the training was received, the name of the competent person who provided the training:

(3) The name of the mine or independent contractor, MSHA mine identification number or independent contractor identification number, and location of training (if an institution, the name and address of the institution).

(4) The statement, “False certification is punishable under §110(a) and (f) of the Federal Mine Safety and Health Act,” printed in bold letters and in a conspicuous manner; and

(5) A statement signed by the person designated in the MSHA-approved training plan for the mine as responsible for health and safety training, that states “I certify that the above training has been completed.””

TIP! – Go to our RESOURCES page for a link to MSHA’s Educational Field and Small Mine Services department. They offer downloadable Training Plan and Record of Training templates.

TIP! – Keep in mind that most mines are very familiar with the 5000-23 Certificate of Training. So, it may be wise to stick with that standard form to avoid any issues with miner operators accepting a compliant Record of training that you developed yourself (even if the one you produced is fully MSHA-compliant).

8 – Part 46 Training Requirements for Contractors

While MSHA expects Part 46 contractors to have all the same documentation and training as miners, there’s specific reference to contractors in Part 46.12 – Responsibilities for Independent Contractor Training.

Part 46.12 states that the mine operator is responsible for providing contractors with:

- Site-specific hazard training

- Information on the training compliance obligations of each independent contractor

That section also states that the independent contractor is responsible for:

- Providing new miner training, newly hired experienced miner training, new task training, and annual refresher training, as appropriate.

- Informing the production operator (mine operator) of any hazards “of which the contractor is aware that may be created by the performance of the contractor’s work at the mine.”

9 – New Miner Training

Since MSHA considers contactors equivalent to miners from a training perspective, the most relevant place to start with is your New Miner Training.

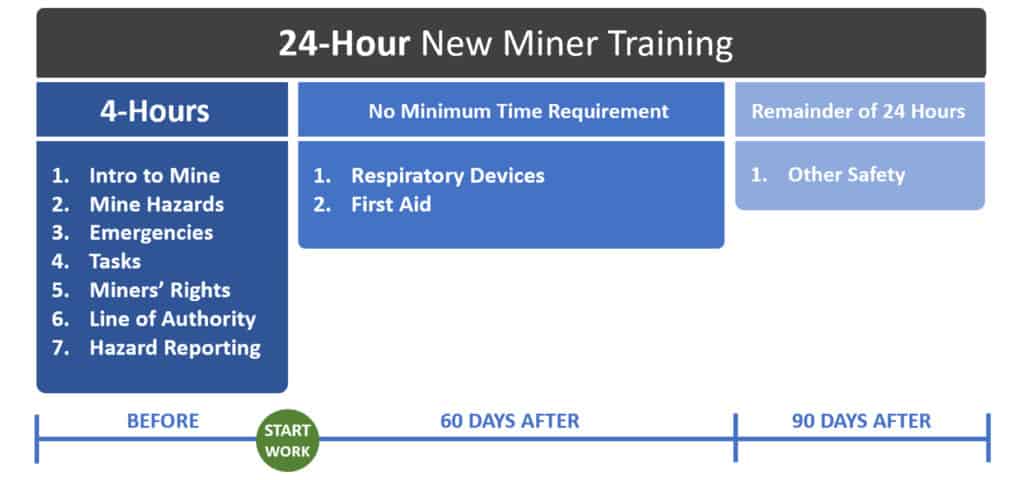

Part 46 requires a minimum of 24 hours of training for New Miners. The training is broken up into required topics that must be covered in defined amounts of time within a defined timeframe.

Here’s what that means:

- Before beginning work at the mine:

- A minimum of 4 hours of training must be provided

- 7 required topics must be covered

- No later than 60 days after beginning

work at a mine:

- No minimum amount of training

- 2 required topics must be covered

- No later than 90 days after beginning

work at a mine:

- The balance, if any, of the 24 hours of training

- Any other subjects that promote health and safety

TIP! – While MSHA allows up to 90 days after starting work at the mine to complete the total 24-hours required for New Miner Training, it’s very common for mine operators and mining contractors to do this a bit differently. In fact, most Part 46 New Miner Training is done in three consecutive 8-hour days of training prior to miners and contractors beginning work at a mine. This approach knocks out all the training in one push so everyone can get right to work and not be bothered by the 60 and 90-day deadlines.

10 – Annual Refresher Training

Meeting the requirements for MSHA’s Part 46 8-Hour Annual Refresher Training is deceptively easy. When you read through the regulations, it looks like you’ll need to cover a bunch of subjects. But on closer scrutiny, you’ll find that while there’s a long list of “recommended” subjects, ONLY ONE SUBJECT IS REQUIRED – Changes at the mine.

“The refresher training must include instruction on changes at the mine that could adversely affect the miner’s health or safety.”

As a contractor, this translates to “changes at your company or facility that could adversely affect your employees’ health or safety.”

So, anything that may have changed at your office, warehouse, lot, or shop can be included. Some examples could be things like:

- New fire extinguishers added

- Changes to fire suppression or sprinkler systems

- An AED (automatic external defibrillator) included in the first aid kit

- Updated fire alarm

- Changes to evacuation plans or emergency procedures

- Changes to parking or traffic patterns

And there’s no minimum amount of training time required on “changes at the mine.” So, you can use your judgement on how long to spend covering this single required subject compared to time on other “recommended” subjects.

The recommended (not required) subjects that MSHA lists in Part 46.8 – Annual Refresher Training include:

- Mandatory health and safety standards

- Information about the physical and health hazards of chemicals in the miner’s work area

- The protective measures a miner can take against these hazards

- The contents of the mine’s HazCom program

- Transportation controls and communication systems

- Escape and emergency evacuation plans

- Firewarning and firefighting

- Ground conditions and control

- Traffic patterns and control

- Working in areas of highwalls

- Water hazards, pits, and spoil banks

- Illumination and night work

- First aid

- Electrical hazards

- Prevention of accidents

- Health

- Explosives

- Respiratory devices

- Equipment Hazards

- Mobile equipment (haulage and service trucks, front-end loaders and tractors)

- Conveyor systems

- Cranes

- Crushers

- Excavators

- Dredges

- Maintenance and repair (use of hand tools and welding equipment)

- Material handling

- Fall prevention and protection

- Working around moving objects (machine guarding)

TIP! – A common misconception about Annual Refresher Training is that it must be done in a single 8-hour session. This isn’t the case. While MSHA requires a minimum of 8 hours of Annual Refresher Training, this training can be credited from sessions spread out across the entire year. And since the ONLY required subject is “changes at the mine that could adversely affect the miner’s health and safety,” you’ve got a lot of flexibility.

MSHA allows for you to credit training time from trainings that happen throughout the year to your Part 46 Annual Refresher Training. For example, the time you spend in monthly safety meetings or periodic first aid and emergency preparation training can be applied to your Annual Refresher Training.

Just be sure to include those training subjects, teaching methods, and competent persons in your Annual Refresher Training Plan.

11 – How to Handle an Inspection

As a contractor, it may be rare that you’re ever inspected by MSHA. But it happens. So, it’s wise to be prepared.

For Part 46, MSHA’s primary goal will be to verify, via compliant documentation, that anyone on your team who is performing work at a mine has completed all required New Miner and Annual Refresher Training.

So, if and when an MSHA inspector comes knocking, they’ll expect to see hard copies of your Training Plan and Records of Training (for New Miner and Annual Refresher Training) for all individuals working at a mine.

TIP! – Keep hard copies of all MSHA documents accessible at your office. It’s also a good idea to keep copies of Records of Training in the vehicles that your team takes to the mine, just in case anyone wants to verify you’re compliant. It can be very helpful to have documents on-hand when your team plans to travel to a mine they haven’t been to before.

12 – Training Options for Contractors

Once the initial shock of all the required training and documentation subsides, the next question is, “How do I get my team of non-miners trained as miners?”

One of the great things about the Part 46 regulations is that they are written and structured in a way that offers lots of flexibility. The primary intent is that mine operators and mining contractors plan and conduct their own training, for their own personnel, with their own resources. While that’s not required, it puts a lot of control in your hands for how you’ll train your team.

Here are some training options based on how contractors typically get their MSHA training done:

- Coordinate with a mine – In preparation for performing work at a surface mine, ask the mine’s safety manager if your team of contractors can join in on their next New Miner Training. It’s very common that mines include contractors in on-site training. This allows the mine operator to oversee and control the training that’s provided to everyone who works on their site.

- Do everything internally – This is a lot more work because you’ll need to ensure you fully understand the documentation and training requirements. You’ll also need to designate competent persons to provide the training, coordinate and conduct the training, and ultimately ensure your documentation is compliant and up to date.

- Send your team to a training facility – MSHA provides a list of training resources across the country who are part of the State Grant Program, which funds miner training programs through universities and other training facilities. That’s a great place to start when looking for Part 46 training resources.

- Bring an external trainer in-house – You can search online for independent mining consultants and trainers who do on-site training. Often, these individuals will be Part 48 MSHA-Approved trainers who can train for Part 46 as well.

- Train your team online – This can be a very cost-effective and flexible option that takes some of the training load off your competent persons. There are a number of eLearning providers of MSHA Part 46 New Miner and Annual Refresher Training to choose from. Some even offer compliant documentation – Training Plan templates partially filled in for you, plus Records of Training in compliant formats upon completion.

13 – Entering a Mine Site

It’s important to understand and respect that every mine operator has the authority to deny access to any individual, with the exceptions of law enforcement and MSHA personnel. Allowing contractors to work on-site is entirely at the discretion of the mine operator.

Mining can be hazardous work and when liability of workers on-site is a concern, mine operators may exert their rights to control access very strictly. So, simply showing compliant documentation of your training doesn’t automatically get you past the gate.

It’s common for mining contractors to enter the realm of MSHA by way of a contract with a single mine to start. You can save yourself a lot of time and headaches by building a rapport with the mine where your team will perform work. If you have questions about MSHA and mine access, just ask them. It’ll be way better to get their input early rather than having your team get turned away at the gate.

Here are a few questions you might ask the mine operator:

- What documentation is required for my team to get on-site and start work?

- Even though MSHA allows you to document your Part 46 training with either a 5000-23 Certificate of Training or a compliant Record of Training that your produce yourself, the mine operator may only accept a 5000-23. That’s their prerogative. So, I typically suggest either checking first with the mine to see what they accept, or just stick with the 5000-23, since everyone’s familiar with that form.

- Can my team take part in New Miner Training that you may have scheduled?

- This is a great way to build a relationship with the mine. And it’s very common for mines to include mining contractors in scheduled training. If you’re able to get your team into an on-site miner training, you’ll have the advantage of getting the exact same training as a new miner AND get documentation that you know the mine will accept.

- Can we schedule a mine tour as part of the required New Miner Training prior to starting work?

- This is an easy one, since it’s a required part of Part 46 New Miner Training. But a tour can be involved and take time. So, prepare to block out at least a couple of hours or more.

- Could your safety manager take a few minutes to look over my Training Plan to make sure I’m on-track?

- If the mine personnel are open to offering guidance, this can a good way to get the mine’s input on your documentation. Ultimately, you’re trying to avoid any costly surprises that can limit your team’s ability to perform work on-site. So, when the mine asks to see your Training Plan or Records of Training, you’ll have a heads-up for how they want to see it. Then, nobody’s ever stopped at the gate.

The better relationship you have with the mine and the better prepared your team is, the less likely they’ll be denied mine access due to something like documentation.

Questions – Comments

If you find anything in this document that you feel is inaccurate or contradicts anything you’re being told from others in the industry, please let me know! It’s extremely important to me to provide you with the most helpful and accurate information available. So please don’t hesitate to contact me and I’ll address your concerns immediately.