While every surface mine is unique, the hazards that surface miners and mining contractors are exposed to are often the same. If you’re preparing to visit or work at a surface mine, here’s what to watch out for to avoid injury at a surface mine.

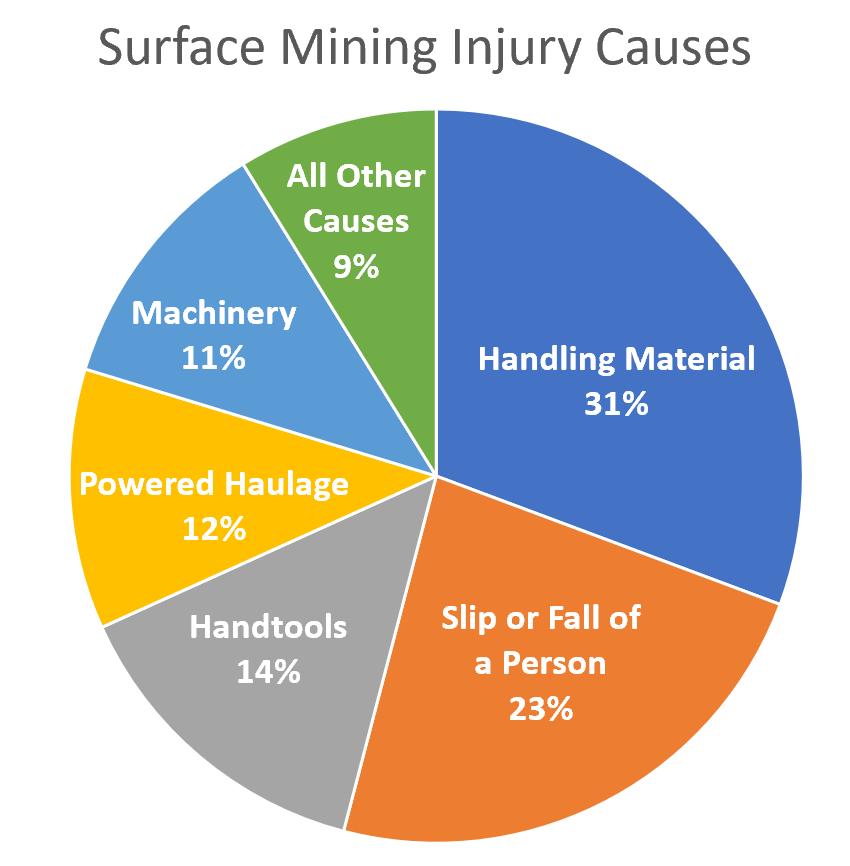

So, what are the top 5 most common hazards at a surface mine? The top 5 most common hazards that cause injuries at a surface mine are:

- Handling Material

- Slips, Trips, and Falls

- Hand Tools

- Powered Haulage

- Machinery

The information in this article is primarily based on the most recent 2018 fatality and injury data published in the Department of Labor’s Mine Injury and Worktime, Quarterly. But it’s not enough to just know what these hazards are. It can be a matter of life and death to understand what actions you can take to avoid them. Here’s some critically important information on hazard recognition and avoidance at surface mines.

How to Recognize and Avoid Handling Material Hazards

MSHA defines “Handling Material” as “lifting, pulling, pushing, shoveling material. The material may be in bags or boxes, or loose sand, coal, rock, timber, etc.” Accidents and resulting injuries directly caused by workers handling material at a surface mine are extremely common.

Back injuries from improper lifting or twisting continue to be one of the most common non-fatal occurrences with days of work lost for miners. Handling materials accounts for a broad range of other injuries, including sprains and strains due to the excessive force and awkward positioning of physical labor at a mine.

TIP! – The prevalence of lifting-related back injuries in the workplace is a clear sign that proper lifting is not common practice. To avoid back injury, be sure to get training on safe lifting techniques. That training should include the following steps:

- Preparation

- Start with a wide stance.

- Squat or lower to a safe position with your back as straight as possible.

- Secure the item with a firm grip and straight arms.

- Lifting / Moving

- Lift with your legs.

- Walk in a way that avoids twisting.

- Lowering

- Lower with your legs.

- Keep arms straight.

- Release your grip when the item is fully lowered.

Hand injuries are also commonly related to hauling material. So be sure to wear gloves to protect from lacerations and bruising.

How to Recognize and Avoid Slip, Trip, and Fall Hazards

MSHA classifies a range of accidents related to “slips or falls from an elevated position or at the same level while getting on or off machinery or haulage equipment that is not moving.” This type of accident also includes “slips or falls while servicing or repairing equipment or machinery” as well as “stepping in a hole.”

TIP! – To avoid falls on or around equipment involving ladders or steps, always ensure you have three points of contact with ladder rungs or steps and handrails. This method increases your stability with each alternating movement using both hands and one foot, then both feet and one hand. You will start and end the process with both hands securely holding handrails or grip points.

TIP! – Also, be sure that ladder rungs and steps are free from debris or slippery material. Take extra precautions and move patiently and deliberately when conditions are wet or muddy.

How to Recognize and Avoid Hand Tool Hazards

MSHA classifies hand tool injuries when they are “related to non-powered tools when being used as hand tools.” These types of hand tool hazards do not include “electric tools or air-powered tools.” Some of the most commonly reported hand tool injuries are the result of improper use of pry bars and hammers.

Pry bars are a type of metal rod often used to apply added force through leverage to clear debris from machinery or move a damaged machine component. Miners are commonly injured when a pry bar they are using unexpectedly releases or slips, causing a fall that puts the miner in a very dangerous situation. Serious and fatal injuries have been reported of miners being impaled on a pry bar, falling into moving machinery, or being crushed under equipment as a result of improver pry bar use.

Use of hammers to strike metal machine parts also creates a metal-on-metal hazard. Depending upon the metal’s hardness and force applied during hammer use, metal from either the hammer or the object being stricken can shear off at very high velocity risking injury.

TIP! – Always lockout, tagout, and block machinery from movement prior to using a pry bar to free material or unfreeze a stuck or damaged part. Be sure that anyone working around you is a safe distance away from material that could get ejected during pry bar use. Avoid applying force to a pry bar in a direction that will place you or others at risk of injury when the pry bar releases. And always wear personal protective equipment (PPE), including gloves, safety glasses, and steel toe work boots.

TIP! – Inspect hammers and equipment prior to striking. Remove hammers and any other tools from service if you observer defects. Wear glove and a face shield in addition to other required PPE.

How to Recognize and Avoid Powered Haulage Hazards

When assessing injuries from powered haulage hazards, MSHA includes accidents caused by the motion of or component failure of these types of equipment:

- Conveyors

- Belt feeders

- Bucket elevators

- Haulage trucks

- Front-end loaders

- Load-haul-dumps

- Forklifts

- Motors and railcars

- Self-loading scrapers or pans

- Mobile cranes (if traveling with a load)

- Shuttle cars

- Cherry pickers

- Vertical manlifts

The range of hazards created by powered haulage is extensive. Because mobile equipment operators often have very limited field of vision, miners can be crushed when working or walking within an operator’s blind spot. Miners attempting to clear debris or inspect rollers too closely can be drawn into moving parts of powerful conveyors moving at high speeds.

TIP! – When walking or working around powered haulage, always wear high visibility clothing and give the vehicle the right of way. Never assume that an equipment operator sees you.

TIP! – Never attempt to step or jump across a moving conveyor. Before working around a conveyor or belt feeder, be sure to locate all emergency stop buttons and cords. And only attempt maintenance or repairs on a conveyor after following all lockout-tagout procedures.

How to Recognize and Avoid Machinery Hazards

MSHA classifies machinery accidents as those that “result from the action or motion of machinery or from failure of component parts.” This includes all electric and air-powered tools and mining machinery, such as:

- Drills

- Tuggers

- Slushers

- Draglines

- Power shovels

- Loading machines

- Compressors

Machinery hazards put body parts at risk of being pinched, crushed, severed, and drawn into a range of machine motions and actions.

Machine motions include:

- Rotating

- Reciprocating

- Transversing

Machine actions include:

- Bending

- Cutting

- Punching

- Shearing

TIP! – The best course of action to avoid machinery hazards is to keep your distance. Avoid wearing loose or dangling clothing and be sure to secure long hair under a hard had. Mine operators should ensure that hazardous machine components are properly guarded and that guarding is only removed what all machine motions and actions have been properly de-energized and blocked.

Related Questions

Common Health Hazards of Mining

There are a number of common health hazards that put miners and mining contractors at risk for long-term health problems. Here are some of the most prevalent hazards miners face each day.

- Respirable Dust – Silica fibers in respirable dust can create permanent lung damage, resulting is silicosis.

- Noise – Prolonged exposure to high levels of noise can cause permanent hearing damage.

- Whole Body Vibration – Working on or in machinery that subjects the body to intense or prolonged vibration can have long-term effects on internal organs.

- UV Exposure – Since many surface mine work is done in the open, miners can be at risk of skin damage or melanoma.

- Musculoskeletal Disorders – Prolonged work in awkward positions can do permanent damage to the spine and other bones and tissue of the body.

- Heat and Cold Stress – Working outside during extreme temperatures can affect mental acuity and limit physical abilities.

How Many Miners Die Every Year?

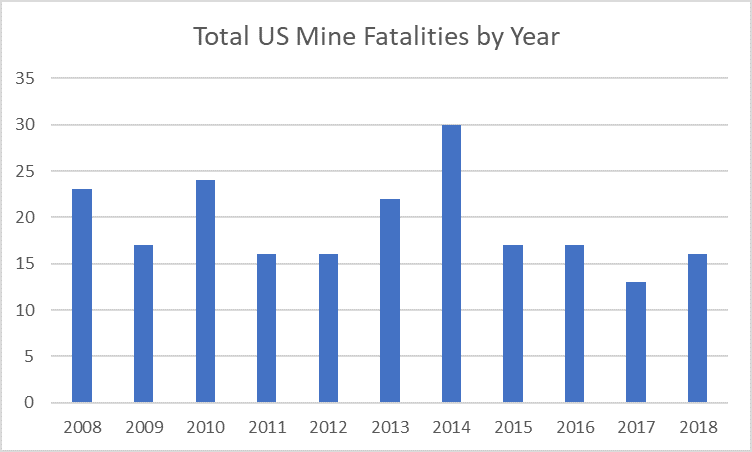

Beginning in 1981, US mine fatalities dropped, and have remained, below 100 deaths per year. Since mine fatality records began in 1911 when the total deaths were 883 for that year, the lowest number of recorded fatalities was in 2017, at 13 deaths. Here are the most recent fatality numbers available from MSHA:

Is Surface Mining Dangerous?

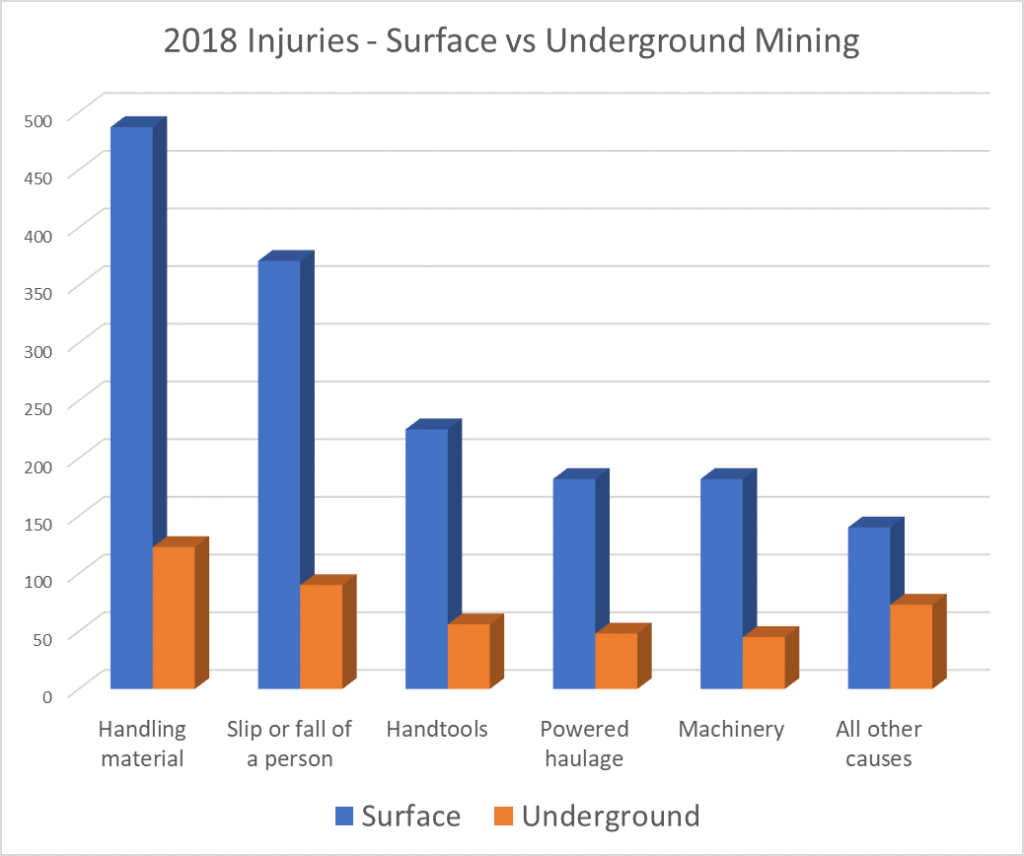

Like many industrial environments, surface mining can dangerous. U.S. Department of Labor data from 2018 suggests that surface mines reported an average of about 4 times the number of injuries reported by underground mines in the top 5 accident categories of:

- Handing material

- Slip or fall of a person

- Handtools

- Powered haulage

- Machinery

- All other accidents