The Mine Safety and Health Administration (MSHA) oversees the U.S. mining industry by administering and enforcing Title 30 in the Code of Federal Regulations (CFR) related to mineral resources. Title 30: Chapter 1 – MSHA, Department of Labor contains over 100 numbered regulatory “parts” within chapters and subchapters, each relating to health and safety standards and training requirements. It’s here, in Part 47, where you’ll find MSHA’s Hazard Communication (HazCom) standard, which defines how chemicals used at mines must be identified, documented, labeled, and communicated to miners.

So, what is MSHA’s HazCom standard and how is it different from OSHA’s alignment with GHS? MSHA’s HazCom standard is a set of regulatory requirements intended to reduce injuries and illnesses by ensuring that each mine operator –

- Identifies the chemicals at a mine,

- Determines which chemicals are hazardous,

- Establishes a hazard communication (HazCom) program, and

- Informs each miner and worker on-site who can be exposed about chemical hazards and appropriate protective measures.

OSHA’s original HazCom standard (HCS) was also intended to improve chemical safety in the workplace but transitioned fully in 2016 to align with the United Nations’ Globally Harmonized System of Classification and Labeling of Chemicals (GHS).

Establishing a means of communication and warnings related to chemical hazards in the workplace provides valuable and potentially life-saving information to those who need it most, the workers who can be exposed. And while MSHA and OSHA are separate agencies within the Department of Labor with their own sets of regulations, there are times when they collaborate and effectively share regulatory space. Regarding chemical hazard communication, both MSHA and OSHA have their own standards, but MSHA has stated that mine operators choosing to adhere to OSHA’s GHS standards are considered compliant with MSHA’s HazCom standard. And while non-mine workplaces throughout the U.S. are subject to the GHS regulations, mine operators may still maintain MSHA’s original HazCom standard. So, in this article, we’ll cover MSHA’s HazCom program in detail to ensure you’ve got all the right info. Then we’ll highlight the major differences between MSHA’s HazCom standard and OSHA’s GHS regulations. Let’s get started!

1 – MSHA’s HazCom Standard

30 CFR Part 47 Hazard Communication (HazCom) provides the purpose, scope, applicability, and training associated with MSHA’s HazCom standard.

It’s important to understand that MSHA’s HazCom Standard is the set of regulations that includes instruction on development and maintenance of a compliant HazCom Program.

MSHA’s Part 47 HazCom standard contains the following Subparts:

A – Purpose, Scope, Applicability, and Initial Miner Training

B – Definitions

C – Hazard Determination

D – HazCom Program

E – Container Labels and Other Forms of Warning

F – Material Safety Data Sheets

G – [Reserved]

H – Making HazCom Information Available

I – Trade Secret Hazardous Chemical

J – Exemptions

We’ll review each of these subparts and spend a bit more time going over Subpart D – HazCom program in more detail.

2 – Subpart A – Purpose, Scope, Applicability, and Initial Miner Training

The purpose of the HazCom Standard is to effectively support MSHA’s mission to “prevent death, illness, and injury from mining and promote safe and healthful workplaces for U.S. miners.” Of course, this set of regulations is intended to contribute to those efforts with a focus on workplace chemicals. Specifically, the purpose of the standard is to ensure that every mine operator in the U.S:

“(a) Identifies the chemicals at the mine,

(b) Determines which chemicals are hazardous,

(c) Establishes a HazCom program, and

(d) Informs each miner who can be exposed, and other on-site operators whose miners can be exposed, about chemical hazards and appropriate protective measures.”

Subpart A applies to all mine operators producing or using hazardous chemicals under either normal or emergency conditions. Mine operators must “instruct each miner with:

- information about the physical and health hazards of chemicals in the miner’s work area,

- the protective measures a miner can take against these hazards, and

- the contents of the mine’s HazCom program.”

3 – Subpart B – Definitions

While each definition in this subpart is important to understand, we’ll focus on the definitions most directly related to development of the HazCom program.

For a link to Part 47 with access to all subparts and definitions, please go to our RESOURCES page.

Critical definitions include the following:

- “Hazardous chemical – Any chemical that can present a physical or health hazard.

- Physical hazard – A chemical for which there is scientifically valid evidence that it is—

(1) Combustible liquid:

(i) A liquid having a flash point at or above 100 °F (37.8 °C) and below 200 °F (93.3 °C); or

(ii) A liquid mixture having components with flashpoints of 200 °F (93.3 °C) or higher, the total volume of which make up 99% or more of the mixture.

(2) Compressed gas:

(i) A contained gas or mixture of gases with an absolute pressure exceeding:

(A) 40 psi (276 kPa) at 70 °F (21.1 °C); or

(B) 104 psi (717 kPa) at 130 °F (54.4 °C) regardless of pressure at 70 °F.

(ii) A liquid having a vapor pressure exceeding 40 psi (276 kPa) at 100 °F (37.8 °C) as determined by ASTM D-323-82.

(3) Explosive: A chemical that undergoes a rapid chemical change causing a sudden, almost instantaneous release of pressure, gas, and heat when subjected to sudden shock, pressure, or high temperature.

(4) Flammable: A chemical that will readily ignite and, when ignited, will burn persistently at ambient temperature and pressure in the normal concentration of oxygen in the air.

(5) Organic peroxide: An explosive, shock sensitive, organic compound or an oxide that contains a high proportion of oxygen-superoxide.

(6) Oxidizer: A chemical, other than an explosive, that initiates or promotes combustion in other materials, thereby causing fire either of itself or through the release of oxygen or other gases.

(7) Pyrophoric: Capable of igniting spontaneously in air at a temperature of 130 °F (54.4 °C) or below.

(8) Unstable (reactive): A chemical which in the pure state, or as produced or transported, will vigorously polymerize, decompose, condense, or become self-reactive under conditions of shock, pressure, or temperature.

(9) Water-reactive: A chemical that reacts with water to release a gas that is either flammable or a health hazard.

- Health hazard – A chemical for which there is statistically significant evidence that it can cause acute or chronic health effects in exposed persons. Health hazard includes chemicals which—

(1) Cause cancer;

(2) Damage the reproductive system or cause birth defects;

(3) Are irritants, corrosives, or sensitizers;

(4) Damage the liver;

(5) Damage the kidneys;

(6) Damage the nervous system;

(7) Damage the blood or lymphatic systems;

(8) Damage the stomach or intestines;

(9) Damage the lungs, skin, eyes, or mucous membranes; or

(10) Are toxic or highly toxic agents.

- Hazard warning – Any words, pictures, or symbols, appearing on a label or other form of warning, that convey the specific physical and health hazards of the chemical.

- Label – Any written, printed, or graphic material displayed on or affixed to a container to identify its contents and convey other relevant information.

- Material safety data sheet (MSDS) – Written or printed material concerning a hazardous chemical which—

(1) An operator prepares in accordance with Table 47.52—Contents of MSDS; or

(2) An employer prepares in accordance with 29 CFR 1910.1200, 1915.1200, 1917.28, 1918.90, 1926.59, or 1928.21 (OSHA Hazard Communication regulations); or

(3) An independent source prepares which contains equivalent information, such as International Chemical Safety Cards (ICSC) and Workplace Hazardous Material Information Sheets (WHMIS).”

4 – Subpart C – Hazard Determination

In order to properly document, label, and warn miners of hazardous chemicals at the mine, each chemical must be identified and researched or tested to determine if it presents a physical or health hazard. This subpart offers some very basic instruction to help mine operators determine what is considered a hazardous chemical whether it brought to the mine, produced at the mine, or mixed at the mine.

Brought To The Mine – For chemicals brought to the mine, the most obvious means of determining if it’s a hazard is to review its MSDS or container label. If either or both should confirm if the chemical is a physical or health hazard.

Produced At The Mine – For chemicals produced at the mine, mine operators should be aware if the chemical presents physical or health hazards through research and review of all available evidence. To help make a hazard determination, this subpart recommends referencing these resources:

- The Occupational Safety and Health Administration (OSHA), 29 CFR part 1910, subpart Z, Toxic and Hazardous Substances.

- American Conference of Governmental Industrial Hygienists (ACGIH), Threshold Limit Values and Biological Exposure Indices.

- U.S. Department of Health and Human Services, National Toxicology Program (NTP), Ninth Annual Report on Carcinogens.

- International Agency for Research on Cancer (IARC), Monographs and related supplements, Volumes 1 through 77.

Mixed At The Mine – For chemicals mixed at the mine, mine operators should determine if a chemical is hazardous by the results of testing or other available scientific evidence. If a chemical mixture that has not been tested is used at a mine, MSHA assumes that a chemical mixture is hazardous if:

- It’s comprised of 1% or more of a hazardous non-carcinogen

- It’s comprised of 0.1% or more of a component considered carcinogenic

- Evidence indicates that a component of the mixture could be released in a concentration that could be hazardous to miners

5 – Subpart D – HazCom Program

In this subpart, MSHA outlines the requirements for and the mandatory contents of a HazCom program.

A HazCom Program is a written document that compiles information, including MSDSs, labels, warnings, and protective measures, on all hazardous chemicals at the mine that a miner could be exposed to.

Both MSHA Part 46 and Part 48 refer to a mine’s HazCom program in the training requirements in the section on “Health and Safety Aspects of Tasks.” All new miners must receive training that includes a review of the contents of the mine’s HazCom program.

MSHA requires that all mine operators must:

- Develop and implement the program in writing.

- Maintain the program as long as the chemical hazards exist at the mine.

- Share the program with other operators whose miners may be exposed to chemical hazards on the mine site.

A written HazCom program must include, at a minimum, the following information:

“(a) How this part is put into practice at the mine through the use of—

(1) Hazard determination,

(2) Labels and other forms of warning,

(3) Material safety data sheets (MSDSs), and

(4) Miner training.

(b) A list or other record identifying all hazardous chemicals known to be at the mine. The list must—

(1) Use a chemical identity that permits cross-referencing between the list, a chemical’s label, and its MSDS; and

(2) Be compiled for the whole mine or by individual work areas.

(c) At mines with more than one operator, the methods for—

(1) Providing other operators with access to MSDSs, and

(2) Informing other operators about—

(i) Hazardous chemicals to which their miners can be exposed,

(ii) The labeling system on the containers of these chemicals, and

(iii) Appropriate protective measures.”

6 – Subpart E – Container Labels and Other Forms of Warning

In this subpart, MSHA outlines the requirements for:

- Container label confirmation, maintenance, and replacement for each hazardous chemical

- Label contents and hazard warning displays

- Label alternatives to labels placed directly on chemical containers

- Label allowances for temporary, portable chemical containers

Container Labels – MSHA considers that if a container is “tagged or marked with the appropriate information, it is labeled.” Mine operators must:

- Not remove of deface containers with existing labels

- Immediately replace labels that are missing, unreadable, or outdated when provided with updated versions by the chemical manufacturers

- Prepare and update a label for chemicals produced at the mine within 3 months of becoming aware of new information about the chemical

Label Contents – To comply with MSHS’s labeling requirements, each chemical label must:

“(a) Be prominently displayed, legible, accurate, and in English;

(b) Display appropriate hazard warnings;

(c) Use a chemical identity that permits cross-referencing between the list of hazardous chemicals, a chemical’s label, and its MSDS; and

(d) Include on labels for customers, the name and address of the operator or another responsible party who can provide additional information about the hazardous chemical.”

Label Alternatives – For individual, stationary process containers, MSHA allows mine operators to use chemical label alternatives that include:

- Signs

- Placards

- Process Sheets

- Batch Tickets

- Operating Procedures

Other label alternatives may be acceptable as long as they:

- Accurately identify the chemical with the associated container

- Meet MSHA’s requirements for a chemical label, communicating the same information as a label

- Remain available to all miners during each work shift in the work area

Label Allowances – MSHA makes some allowances for temporary, portable chemical containers used in the workplace. Mine operators are not required to apply labels to these types of containers in situations where the miner using the container:

- The miner is trained and aware of the chemical’s identity, hazards, and protective measure required to prevent exposure

- Leaves the container empty after use to avoid accidental exposure to others

If these conditions aren’t met, the mine operator must, at a minimum, label the temporary, portable container with the common name of its chemical to inform miners and others of its contents.

7 – Subpart F – Material Safety Data Sheets (MSDS)

An MSDS is a document for each chemical that outlines a specified set of information, including the chemical’s identity, properties, physical and health hazards, and protective measures that workers must take to prevent harmful exposure.

MSHA allows for this document to be stored in any media format that does not restrict availability or access by miners. MSDSs must remain available for miners to access during work shifts in the areas in which the chemicals are used or in a readily accessible location in an emergency.

MSHA requires that mine operators maintain an MSDS for each chemical as long as it’s known to be produced or used onsite. Similar to MSHA’s label requirements, the MSDS must be updated within 3 months of the mine operator becoming aware of “significant or new” information related to a chemical’s hazards or protective measures. And mine operators must notify miners at least 3 months prior to disposing of MSDSs that had been in use at the mine.

For chemicals brought onsite, the mine operator must:

- Use the MSDS from the chemical manufacturer,

- Develop their own version of an MSDS for the chemical, or

- Obtain an accurate MSDS from another source.

When information within an MSDS is discovered to be inaccurate, the mine operator must:

- Obtain an accurately updated version as soon as possible

- Replace the outdated version as soon as an accurately updated version can be produced or obtained

MSDS Contents – MSHA requires that an MSDS include the following information, ensuring that it is accurate, legible, and in English:

“(1) Identity – The identity of the chemical or, if the chemical is a mixture, the identities of all hazardous ingredients. See §47.21 (Identifying hazardous chemicals).

(2) Properties – The physical and chemical characteristics of the chemical, such as vapor pressure and solubility in water.

(3) Physical hazards – The physical hazards of the chemical including the potential for fire, explosion, and reactivity.

(4) Health hazards – The health hazards of the chemical including—

(i) Signs and symptoms of exposure,

(ii) Any medical conditions which are generally recognized as being aggravated by exposure to the chemical, and

(iii) The primary routes of entry for the chemical, such as lungs, stomach, or skin.

(5) Exposure limits – For the chemical or the ingredients of a mixture—

(i) The MSHA or OSHA permissible limit, if there is one, and

(ii) Any other exposure limit recommended by the preparer of the MSDS.

(6) Carcinogenicity – Whether the chemical or an ingredient in the mixture is a carcinogen or potential carcinogen. See the sources specified in §47.21 (Identifying hazardous chemicals).

(7) Safe use – Precautions for safe handling and use including—

(i) Appropriate hygienic practices,

(ii) Protective measures during repair and maintenance of contaminated equipment, and

(iii) Procedures for clean-up of spills and leaks.

(8) Control measures – Generally applicable control measures such as engineering controls, work practices, and personal protective equipment.

(9) Emergency information

(i) Emergency medical and first-aid procedures; and

(ii) The name, address, and telephone number of the operator or other responsible party who can provide additional information on the hazardous chemical and appropriate emergency procedures.

(10) Date prepared – The date the MSDS was prepared or last changed.”

8 – Subpart H – Making HazCom Information Available

MSHA requires that mine operators grant access to all MSDSs and HazCom materials upon request with certain exceptions we’ll cover in a moment. If copies HazCom materials are requested, they first copies must be at no cost to the person or organization making the request. If fees are charged for subsequent copies, those fees must be “non-discriminatory and reasonable.”

Also, mine operators must provide customers who request information on hazardous chemicals produced at the mine with copies of all chemical labels, any additional label information, and the associated MSDS for the chemical.

9 – Subpart I – Trade Secret Hazardous Chemical

MSHA allows for withholding of chemical information in certain cases related to trade secrets. In very general terms, a trade secret is a legal designation for information related to how a product is formulated or produced. This designation of a trade secret as a form of intellectual property offers the owner of the product certain legal protections from disclosing information to the general public.

For a mine operator to claim a trade secret exemption from disclosure of a chemical’s identity, certain criteria must be met. MSHA requires that mine operators:

- Provide information to MSHA that supports the claim that the chemical is a trade secret

- Identify the chemical without disclosing the trade secret

- States that the chemical is a trade secret in the MSDS

However, the mine operator is still required to disclose the chemical’s identity upon request to:

- Miners

- Designated miners’ representative

- Health professionals

- MSHA representatives

If MSHA grants trade secret status based on the mine operator’s claim after disclosure of the chemical identity, MSHA doesn’t require disclosure of process or mixture percentages.

During a medical emergency, the mine operator must immediately disclose the identity of the trade secret chemical upon request by a health professional who deems the information necessary for treatment of an affected or exposed person.

There are also some non-emergency situations in which a mine operator is required to disclose the identity of a trade secret chemical upon written request. This request must:

- Provide a detailed description of the occupational health need for the information

- Explain the need for added details related to the chemical’s properties and health effects, exposure control, exposure monitoring, and diagnosing and treating harmful exposures

- Describe procedures employed to maintain confidentiality of the trade secret

- Include an additional confidentiality agreement that the person requesting the information will use it solely to address health and treatment needs and not disclose the secret information

Confidentiality agreements related to trade secrets must also allow for:

- Restricting use of the information to health treatment purposes

- Disclosure to MSHA of the trade secret chemical by the exposed miner, miners’ representative, or health professional, with consideration to informing the mine operator prior to or at the same time as disclosure to MSHA

- Appropriate legal remedies for breach of agreement terms

Mine operators are afforded the opportunity to deny written requests for disclosure under certain circumstances.

10 – Subpart J – Exemptions

MSHA allows certain exemptions from this HazCom standard and labeling requirements.

The following hazard types are exempt from the HazCom standard under these specified conditions:

Insignificant Risk of Exposure – Hazardous chemicals that either release no more than insignificant amounts or pose no physical or health risk of exposure during normal conditions of use are exempt.

Biological Hazards – Miner operators are not required to include biological elements or naturally occurring organisms, such as poisonous plants, insects, and micro-organisms, in their HazCom programs.

Consumer Products – Items purchased for consumer use or hazardous substances regulated by the Consumer Products Safety Commission (CPSC) that are used for their intended purposes within ordinary use durations are exempt.

Other Products and Additives – A range of other consumer products, medical products, and additives are exempt when used as intended. These items include cosmetics, food, food and color additives, drinks, alcohol, tobacco, medical or veterinary devices, and flavor and fragrance ingredients.

Radiation – Ionizing and non-ionizing radiation, including alpha, gamma, microwaves, and x-rays are exempt from the HazCom standard.

Wood Products – Wood products and lumber that pose no exposure risk under normal conditions are exempt. However, wood that is treated with hazardous chemicals and may be cut or sanded is not exempt.

While the items above are exempt from the HazCom standard, the following items are exempt only from MSHA’s hazardous chemical labeling requirements.

Chemical Substances – Chemical substances, consumer products, hazardous substances, and pesticides that are kept in original consumer packaging with labels that meet federal requirements are exempt from MSHA’s HazCom labeling requirements.

Hazardous Substances – Hazardous substances are exempt from labeling “when the subject of remedial or removal action under the Comprehensive Environmental Response, Compensation and Liability Act (CERCLA) in accordance with EPA regulations.”

Hazardous Waste – No labeling is required for hazardous waste that is regulated by the Environmental Protection Agency (EPA).

Raw Materials Mined or Processed On-site – No labeling is required from raw materials being mined or processed on-site unless the material is mixed and stored in a container with a hazardous material, resulting in a hazardous mixture.

Wood Products – MSHA allows all wood and wood products to be exempt from labeling requirements.

11 – Main Differences Between MSHA’s HazCom Standard and OSHA’s GHS

While there are several key differences between MSHA and OSHA hazard communication standards, MSHA considers any mine operator who is compliant with GHS to be also compliant with its own HazCom standard. This allows mine operators to decide which standard they’ll comply with.

And although both standards are acceptable, here are some of the main differences between the two:

Scope – The primary difference between to two standards is that OSHA’s Globally Harmonized System of Classification and Labeling of Chemicals (GHS) is a much more modern and internationally adopted set of requirements established by the United Nations. MSHA’s HazCom is focused only on U.S. mines.

Hazard Classifications – GHS established a universal set of hazard classifications based on standardized testing and shared criteria. Classifications include:

- Explosives

- Flammable Gases

- Flammable Aerosols

- Oxidizing Gases

- Gases Under Pressure

- Flammable Liquids

- Flammable Solids

- Self-Reactive Substances and Mixtures

- Pyrophoric Liquids

- Pyrophoric Solids

- Self-Heating Substances and Mixtures

- Substances and Mixtures, which in contact with water, emit flammable gases

- Oxidizing Liquids

- Oxidizing Solids

- Organic Peroxides

- Corrosive to Metals

- Acute Toxicity

- Skin Corrosion/Irritation

- Serious Eye Damage/Eye Irritation

- Respiratory Sensitizer

- Skin Sensitizer

- Germ Cell Mutagenicity

- Carcinogenicity

- Toxic to Reproduction

- Effect on or via Lactation

- Specific Target Organ Toxicity Following Single Exposure

- Aspiration Hazard

- Acute Hazards to the Aquatic Environment

- Chronic Hazards to the Aquatic Environment

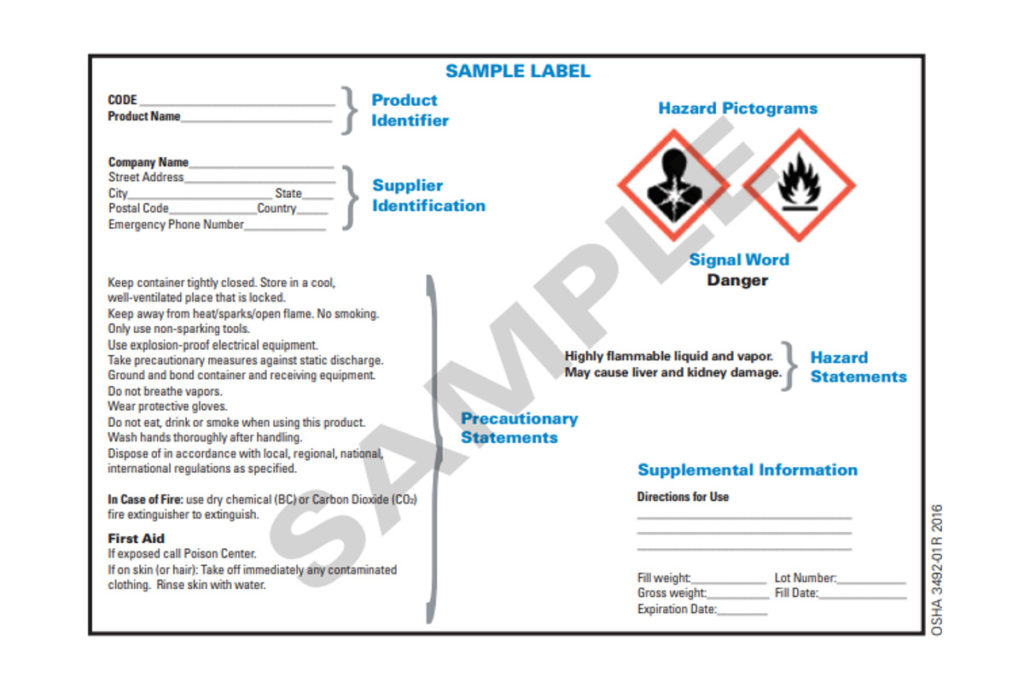

Labeling Requirements – Instead of MSHA’s relatively basic set of label requirements, GHS requires a standardized set of information and symbols that include:

- Harmonized Signal Word

- Pictogram

- Product Identifier

- Supplier Identification

- Hazard Statement

- Precautionary Statement

- Hazard Pictograms

SDS vs MSDS – GHS established the use of the Safety Data Sheet (SDS) that standardized both the information and format of hazardous chemical documentation. While the MSDS required a standard set of information, its format was not universal. So, there were many potentially confusing variations of MSDSs.

12 – Questions?

If you have further questions about MSHA’s HazCom Standard and how to create a compliant HazCom Program, go to our RESOURCES page for links to MSHA Part 47 Hazard Communication (HazCom) and other useful information.