While the Mine Safety and Health Administration (MSHA) takes an active role in testing, approving, and certifying certain types of mining equipment, personal protective equipment (PPE) typically falls outside of those regulatory efforts. However, through Title 30 of the Code of Federal Regulations (30 CFR), MSHA makes certain requirements for the use and maintenance of PPE in support of its mission to “to prevent death, illness, and injury from mining and promote safe and healthful workplaces for U.S. miners.” And although MSHA requires use of a complete scope of PPE as a last line of defense to protect works from physical and chemical hazards, the organization provides little guidance on specific products that meet accepted safety standards.

So, what personal protective equipment is best for mining? Based on MSHA, OSHA, and other federal standards, personal protective equipment for mining falls into these categories:

- Hard hats

- Eye protection from general injury and grinding wheel

- Hearing protection

- Respiratory devices and self-contained self-rescue (SCSR) equipment

- Hand protection

- Protective clothing from irritants and hot work

- High visibility vests and clothing

- Life jackets and belts

- Safety belts and lines

- Protective footwear

- Flashlights and headlamps

- First aid material

MSHA’s Approval and Certification Center (A&CC) typically

oversees testing and approval of equipment components and machinery that could represent

an ignition source for mine environments that may be susceptible to explosion. Underground

coal and gassy mines where methane and combustible coal dust can accumulate

represent potentially hazardous environments for certain electrical and

mechanical components. So, the majority of equipment approved and certified by

the A&CC are items related to conveyors, motors, diesel equipment, dust

collection, hoses, batteries, electrical wiring, and flame-resistant components.

With the exceptions of some self-contained self-recue devices and personal

flashlights/headlamps, the A&CC doesn’t tend to work with PPE.

However, in situations where MSHA regulations require the use of PPE but doesn’t

specifically set or regulate performance, testing, or approval standards for

the equipment, MSHA often considers products that meet the American National

Standards Institute (ANSI) and National institute of Safety and Health (NIOSH) standards

as acceptable.

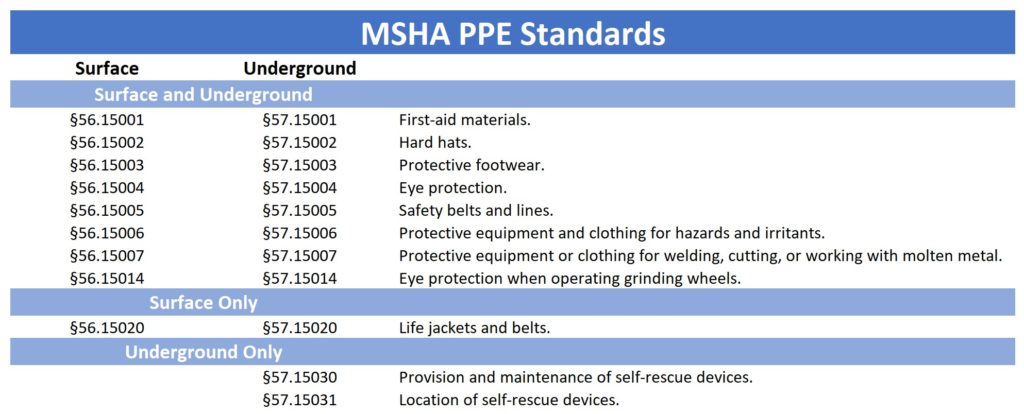

30 CFR sets forth identical standards for PPE use for both surface (Part 56.15001 – 56.14020) and underground (Part 57.15001 – 57.15020) miners with Part 57 for underground miners adding two sections (Part 57.15030 and 57.15031) related to accessibility, maintenance, and placement of self-rescue devices.

This product use and selection guide offers product options related to the primary MSHA regulations related to personal protection, plus several other regulations and product types relevant to working at a mine.

Hard Hats

MSHA Standards – 30 CFR Part 56.15002 for Surface / Part 57.15002 for Underground

“Hard hats – All persons shall wear suitable hard hats when in or around a mine or plant where falling objects may create a hazard.”

ANSI Standards – Z89.1 for industrial head protection and Z89.2 for electrical workers

Product Options:

Comfo-Cap – 91522

- Brand – MSA

- Approvals – ANSI Z89.1-2014 and CSA Z94.1-2015

- Check pricing

Skullgard Full Brim – 475407

- Brand – MSA

- Approvals – ANSI Z89.1-2014

- Check pricing

Ridgeline Full Brim

- Brand – Pyramex

- Approvals – ANSI Z89.1-2009 standards, type 1, Class C, G, and E

- Check pricing

Eye Protection From General Injury And Grinding Wheel

MSHA Standards – 30 CFR Part 56.15004 for Surface / Part 57.15004 for Underground

“Eye protection – All persons shall wear safety glasses, goggles, or face shields or other suitable protective devices when in or around an area of a mine or plant where a hazard exists which could cause injury to unprotected eyes.”

MSHA Standards – 30 CFR Part 56.15014 for Surface / Part 57.15014 for Underground

“Eye protection when operating grinding wheels – Face shields or goggles in good condition shall be worn when operating a grinding wheel.”

Product Options:

Polycarbonate Diablo Safety Glasses, Clear – SC-260

- Brand – Rugged Blue

- Approvals – ANSI/ISEA Z87.1-2010 and EN 166

- Check pricing

Virtua CCS Protective Eyewear – 11872-00000-20

- Brand – 3M

- Approvals – ANSI/ISEA Z87.1-2010 and EN 166

- Check pricing

Wraparound Veratti 307 Safety Glasses

- Brand – Encon

- Approvals – ANSI/ISEA Z87.1-2010 and CSA Z94.3-2007

- Check pricing

V30 Nemesis Safety Glasses – 14481

- Brand – Kleenguard

- Approvals – ANSI/ISEA Z87.1-2010

- Check pricing

Vertoggle Goggle – 10150069

- Brand – MSA

- Approvals – ANSI/ISEA Z87.1-2010 and CSA Z94.3-2007

- Check pricing

Advantage Series All-Purpose Face Shield – S30120

- Brand – Sellstrom

- Approvals – ANSI/ISEA Z87.1

- Check pricing

Hearing Protection

30 CFR Part 62.160 – Hearing Protectors

“(a) A mine operator must provide a hearing protector to a miner whose noise exposure equals or exceeds the action level under §62.120 of this part. In addition, the mine operator must:

(1) Train the miner in accordance with §62.180 of this part;

(2) Allow the miner to choose a hearing protector from at least two muff types and two plug types, and in the event dual hearing protectors are required, to choose one of each type;

(3) Ensure that the hearing protector is in good condition and is fitted and maintained in accordance with the manufacturer’s instructions;

(4) Provide the hearing protector and necessary replacements at no cost to the miner; and

(5) Allow the miner to choose a different hearing protector(s), if wearing the selected hearing protector(s) is subsequently precluded due to medical pathology of the ear.

(b) The mine operator must ensure, after satisfying the requirements of paragraph (a) of this section, that a miner wears a hearing protector whenever the miner’s noise exposure exceeds the permissible exposure level before the implementation of engineering and administrative controls, or if the miner’s noise exposure continues to exceed the permissible exposure level despite the use of all feasible engineering and administrative controls.

(c) The mine operator must ensure, after satisfying the requirements of paragraph (a) of this section, that a miner wears a hearing protector when the miner’s noise exposure is at or above the action level, if:

(1) The miner has incurred a standard threshold shift; or

(2) More than 6 months will pass before the miner can take a baseline audiogram.”

TIP – For more on MSHA’s Hearing Conservation Program (HCP), check out our article, “How To Comply With MSHA’s Hearing Conservation Program.”

Product Options:

SparkPlugs Tapered Uncorded Foam Ear Plugs – 33dB Highest NRR

- Brand – Moldex

- Approvals – ANSI S3.19-1974

- Check pricing

Left/Right Headband Earmuff, High, 28 dBA NRR– 10087399

- Brand – MSA

- Approvals – ANSI S3.19-1974

- Check pricing

Left/Right Passive Cap-Mounted Earmuff, High, 28 dBA NRR – 10087422

- Brand – MSA

- Approvals – ANSI S3.19-1974 and CSA Class A

- Check pricing

Respiratory Devices and Self-Contained Self-Rescue (SCSR) Equipment

MSHA Standards – 30 CFR Part 57.15030 Underground

“Provision and maintenance of self-rescue devices – A 1-hour self-rescue device approved by MSHA and NIOSH under 42 CFR part 84 shall be made available by the operator to all personnel underground. Each operator shall maintain self-rescue devices in good condition.”

MSHA Standards – Part 57.15031 for Underground

“Location of self-rescue devices – (a) Except as provided in paragraph (b) and (c) of this section, self-rescue devices meeting the requirements of standard 57.15030 shall be worn or carried by all persons underground.

(b) Where the wearing or carrying of self-rescue devices meeting the requirements of standard 57.15030 is hazardous to a person, such self-rescue devices shall be located at a distance no greater than 25 feet from such person.

(c) Where a person works on or around mobile equipment, self-rescue devices may be placed in a readily accessible location on such equipment.”

Prior to providing reusable respirators to miners, mine operators must ensure proper fit through a series of individual tests that may include a:

- Negative pressure fit check

- Positive pressure fit check

- Qualitative fit test

- Quantitative fit test

Proper respirator fit also requires that the wearer removes facial hair and has no medical condition that affects the seal against the skin around the respirator.

Product Options:

Particulate Respirator with Cool Flow Valve – 8210

- Brand – 3M

- Approvals – NIOSH Approved for 95% Filtration

- (Does not require fit testing)

- Check pricing

(Pictured without filter cartridges)

Advantage 420 Series Half-Mask Respirator – 10102184

- Brand – MSA

- Approvals – NIOSH Approved

- Check pricing

Advantage 4100 Series Full-Facepiece Silicone Respirator – 10083802

- Brand – MSA

- Approvals – NIOSH 42 CFR Part 84

- Check pricing

M-20 Belt-Wearable Self Contained Self Rescuer (SCSR)

- Brand – Ocenco

- Approvals – NIOSH/MSHA

- Check manufacturer site for product specifications and to find a distributor

- Note – Due to product configurations and use scenarios, Ocenco prefers direct contact to ensure customers get products appropriate for their needs.

W65 Self-Rescuer Respirators, Carbon Monoxide – 454-461100

- Brand – MSA

- Approvals – NIOSH TN16083AL

- Check pricing

Hand Protection

Occupational Safety and Health Standards – Subpart I – Personal Protective Equipment

Part 1910.138 – Hand Protection

“(a) General requirements. Employers shall select and require employees to use appropriate hand protection when employees’ hands are exposed to hazards such as those from skin absorption of harmful substances; severe cuts or lacerations; severe abrasions; punctures; chemical burns; thermal burns; and harmful temperature extremes.

(b) Selection. Employers shall base the selection of the appropriate hand protection on an evaluation of the performance characteristics of the hand protection relative to the task(s) to be performed, conditions present, duration of use, and the hazards and potential hazards identified.”

Product Options:

Meta-Miner Mechanics Gloves – 488

- Brand – Illinois Glove Company

- Approvals – ASTM D2632: Impact Resistance; ASTM D3884-92: Abrasion Resistance; ASTM F1790-97: Cut Resistance

- Check pricing

Original Work Gloves

- Brand – Mechanix Wear

- Approvals – EN 388: 2016

- Check pricing

UltraTech Mechanics Gloves – MC503

- Brand – MCR Safety

- Approvals – ANSI/ISEA 105 2016 Cut Protection Level A6

- Check pricing

Protective Clothing From Irritants And Hot Work

MSHA Standards – 30 CFR Part 56.15006 Surface / Part 57.15006 for Underground

“Protective equipment and clothing for hazards and irritants – Special protective equipment and special protective clothing shall be provided, maintained in a sanitary and reliable condition and used whenever hazards of process or environment, chemical hazards, radiological hazards, or mechanical irritants are encountered in a manner capable of causing injury or impairment.”

MSHA Standards – 30 CFR Part 56.15007 Surface / Part 57.15007 for Underground

“Protective equipment or clothing for welding, cutting, or working with molten metal – Protective clothing or equipment and face shields, or goggles shall be worn when welding, cutting, or working with molten metal.”

Product Options:

Tyvek 400 Disposable Protective Coverall with Respirator-Fit Hood and Elastic Cuff – TY127S

- Brand – Dupont

- Approvals – 16 CFR 1610 Class 1

- Check pricing

Contractor Flame Resistant (FR) Coveralls w/Reflective Tape – DC1RR40T

- Brand – MCR Safety

- Approvals – NFPA 2112 UL Certified – ASTM F1506 Electric Arc Protection Standard – NFPA 70E Hazard / Risk Category HRC2 – ATPV ASTM 1959 9.3 cal/cm – ASTM 1930

- Check pricing

Flame-Resistant Heavy Duty Leather Welding Jacket – K2989L

- Brand – Lincoln Electric

- Approvals – Flame resistant leather

- Check pricing

High Visibility Vests And Clothing

Working around large, mobile haulage equipment can be extremely dangerous for pedestrians. And while MSHA doesn’t yet have specific regulations related to high visibility (hi-viz / hi vis / hivis) and reflective clothing, OSHA and ANSI/ISEA 107-2010 do. Therefore, hi-viz Class 2 and 3 reflective garments are required PPE at mine sites.

Product Options:

Economy Class 2 Mesh Safety Vest

- Brand – MCR Safety

- Approvals – ANSI / ISEA Class 2

- Check pricing

Safety Yellow Reflective Safety Vest

- Brand – Safety Depot

- Approvals – ANSI Class 2

- Check pricing

Life Jackets And Belts

MSHA Standards – 30 CFR Part 56.15020 Surface / Part 57.15020 for Surface Areas of Underground

“Life jackets and belts – Life jackets or belts shall be worn where there is danger from falling into water.”

MSHA Best Practice – “Always wear a Coast Guard approved Type I or Type V personal flotation device (PFD) when working around water, even when inside mobile equipment.”

Product Options:

A-33 In-Sight Automatic Inflatable Work Vest

- Brand – Kent

- Details – Minimum buoyancy of 35 lbs. when fully inflated / Automatically inflates upon immersion in water or when the wearer pulls the “Jerk to Inflate” handle

- Approvals – Type V USCG Approved

- Check pricing

Vinyl Dip Commercial Vest

- Brand – Kent

- Details – Minimum 17.5 lbs. of buoyancy / Reflective panels on front and back / Oil and chemical resistant

- Approvals – Type V USCG Approved

- Check pricing

Safety Belts And Lines

MSHA Standards – 30 CFR Part 56.15005 Surface / Part 57.15005 for Underground

“Safety belts and lines – Safety belts and lines shall be worn when persons work where there is danger of falling; a second person shall tend the lifeline when bins, tanks, or other dangerous areas are entered.”

Product Options:

V-SHOCK Mini Personal Fall Limiter

- Brand – MSA

- Approvals – ANSI Z359.14 (Class B) / CSA Z259.2.2 / OSHA Fall Standard

- Check pricing

Nylon and Polyester Web Reinforced Miner’s Body Work Belt – 03194

- Brand – Elk River

- Approvals – Conforms to OSHA 29 CFR 1910 Fall Standards

- Check pricing

Miller Single D-Ring Body Belt – 3NA/MBK

- Brand – Honeywell

- Approvals – Meets all applicable OSHA, ANSI and CSA Standards

- Check pricing

Seraph Universal Harness – 11160 M-L

- Brand – Guardian Fall Protection

- Approvals – ANSI Z359.11-14, ANSI A10.32-12, OSHA 1926 Subpart M, OSHA 1910

- Check pricing

Evotech Lite Line Harness– 10155559

- Brand – MSA

- Approvals – ANSI Z359.11-14, ANSI A10.32-12, OSHA 1926 Subpart M, OSHA 1910

- Check pricing

Protective Footwear

MSHA Standards – 30 CFR Part 56.15003 Surface / Part 57.15003 for Underground

“Protective footwear – All persons shall wear suitable protective footwear when in or around an area of a mine or plant where a hazard exists which could cause an injury to the feet.”

Product Options:

Boondock 6″ Composite Toe Waterproof Industrial & Construction Shoe, Size 10

- Brand – Timberland PRO

- Approvals – ASTM F1671-07 / ASTM F2412-11 / ASTM F2413-11 I/75 / C/75 / CSA-Z195-14 Grade 1

- Check pricing

10-Inch Lace Up Mining Boot, Size 10.5

- Brand – Oliver Footwear by Honeywell

- Approvals – ASTM F2413-11 M I/75 C/75 Mt/75 PR SD

- Check pricing

Miner 49er Mining Boot, Steel Toe & Plate Construction

- Brand – Viking

- Approvals – ANSI Z41 Part 99 / ASTM F2413-11 Grade 1 Steel Toe / CSA Z195-14/Plate

- Check pricing

Flashlights And Headlamps

MSHA Standards – 30 CFR Part 20.8 Surface and Underground

“Electric mine lamps – Specific requirements – Class 1 – Class 1 includes hand lamps, signal lamps, inspection lamps, flashlights, and animal lamps which are operated by small storage batteries or dry cells.“

Since electric lighting products are one of the few PPE items for which MSHA provides approval oversight, we’ll provide additional Class 1 lamp specifications required to protect miners from explosion hazards:

- “(a) Protection against explosion hazards. Unless properly designed, class 1 lamps present two sources of probable explosion hazards: Ignition of an explosive atmosphere by the heated filament of the bulb in case the bulb glass is accidentally broken, and ignition by electric sparks or arcs from the battery or connections thereto. MSHA’s therefore, requires the following safeguards:

- (1) Safety device or design. The lighting unit shall have a safety device to prevent the ignition of explosive mixtures of methane and air if the bulb glass surrounding the filament is broken. Alternatively, if the lamp is designed and constructed of materials that will prevent the ignition of explosive mixtures of methane and air by protecting the bulb from breakage and preventing exposure of the hot filament, no separate safety device is required. Alternative designs will be evaluated by mechanical impact tests, temperature tests and thermal shock tests to determine that the protection provided is no less effective than a safety device.

- (2) Safety device (protection). The design of the safety device and the housing which protects it shall be such that the action of the safety device is positive; yet the lamp shall not be too readily extinguished during normal service by the unnecessary operation of the device.

- (3) Locks or seals. For lamps other than flashlights, all parts, such as bulb housing and battery container, through which access may be had to live terminals or contacts shall be adequately sealed or equipped with magnetic or other equally reliable locks to prevent opening by unauthorized persons. For flashlights, provision shall be made for sealing the battery container.

- (4) Battery current restricted. Unless all current-carrying parts including conductors, are adequately covered and protected by the sealed or locked compartments, the maximum possible current flow through that part shall be limited by battery design, or by an enclosed-type fuse inside the sealed or locked container, to values that will not produce sparks or arcs sufficient to ignite an explosive mixture of methane and air.

- (b) Protection against bodily hazard. This hazard is chiefly due to the possible burning of the user by electrolyte spilled from the battery. MSHA, therefore, requires that:

- (1) Spilling of electrolyte. The lamp shall be so designed and constructed that when properly filled the battery will neither leak nor spill electrolyte under conditions of normal use. Lamps passing a laboratory spilling test will be considered satisfactory in this respect, contingent upon satisfactory performance in service.

- (2) Corrosion of battery container. The material of which the container is made shall resist corrosion under conditions of normal use.”

The following products meet or exceed MSHA’s requirements for personal lighting.

Product Options:

XPR-5522GMX Intrinsically Safe Permissible Light Flashlight w/Dual Magnets-Rechargeable

- Brand – Nightstick

- Approvals – MSHA Permissible Flashlight

- (Nightstick Approved Product Finder)

- Check pricing

Endura Pro Haz-Lo Low Profile Multi Function Headlamp

- Brand – Streamlight

- Approvals – MSHA Permissible Flashlight, Approval No. 20-A190001-0

- (Tested for Intrinsic Safety in Methane-Air mixtures only.)

- Check pricing

XPP-5456G Dual-Light Multi-Function Headlamp

- Brand – Nightstick

- Approvals – MSHA Permissible Flashlight

- Check pricing

TIP! – Flashlights fall into a category of products that MSHA officially approves through the A&CC. You can find a link to a list of all approved flashlight and headlamp products on our RESOURCES page.

First Aid Material

MSHA Standards – 30 CFR Part 56.15001 Surface / Part 57.15001 for Underground

“First-aid materials – Adequate first-aid materials, including stretchers and blankets, shall be provided at places convenient to all working areas. Water or neutralizing agents shall be available where corrosive chemicals or other harmful substances are stored, handled, or used.”

Product Options:

90% Wool Blanket, Olive Green, 4.0 lbs, 66″x90″, Survival & Emergency Preparedness

- Brand – EKTOS

- Details – 90% wool – Mildew, static, and fire resistant

- Check pricing

EMS Portable Stretcher

- Brand – Line2 Design

- Check pricing

- NOTE – Research on use of stretcher types in emergency mining situations indicates that soft stretchers and backboard stretchers take less time to enter refuge alternatives (RAs) than splint stretchers. See our RESOURCES page for a link to that research.

EMS Portable Transfer Unit – 70095

- Brand – Line2 Design

- Details – 40″ x 80″ / 14 Handles / Transports up to 1,500 lbs

- Check pricing

Physicians Care 24-102 Wall Mountable Eye and Skin Flush Station with Two 16 oz Bottles

- Brand – Pac-Kit Safety Equipment Company

- Check pricing

Mine First Aid Station JSA-760

- Brand – Junkin

- Approvals – Content meet MSHA, Title 30 Code of Federal Regulations

- Check pricing

First Aid Kit – Complete Emergency Response Trauma Bag – for Natural Disasters – 9970

- Brand – MFASCO

- Check pricing

Suggestions?

If you have additional thoughts on products that are popular at your mine or suggestions for critical PPE options we may have missed, please let us know! Just CONTACT US and we’ll adjust our list appropriately.

Related Questions

What are the most common mining fatalities in the U.S.?

The 5 most common causes of mining fatalities are:

- Powered Haulage

- Machinery

- Falling or Sliding Material

- Fall of a Face, Rib, or Highwall

- Slip or Fall of a Person

For more details, check out our article, “The 5 Most Common Mining Fatalities – Probably Not What You’d Think.”

What is MSHA’s HazCom Standard?

MSHA’s HazCom standard is a set of regulatory requirements intended to reduce injuries and illnesses by ensuring that each mine operator –

- Identifies the chemicals at a mine,

- Determines which chemicals are hazardous,

- Establishes a hazard communication (HazCom) program, and

- Informs each miner and worker on-site who can be exposed about chemical hazards and appropriate protective measures.

OSHA’s original HazCom standard (HCS) was also intended to improve chemical safety in the workplace but transitioned fully in 2016 to align with the United Nations’ Globally Harmonized System of Classification and Labeling of Chemicals (GHS).

For more details, check out our article, “What Is MSHA’s HazCom And How Is It Different From GHS?”